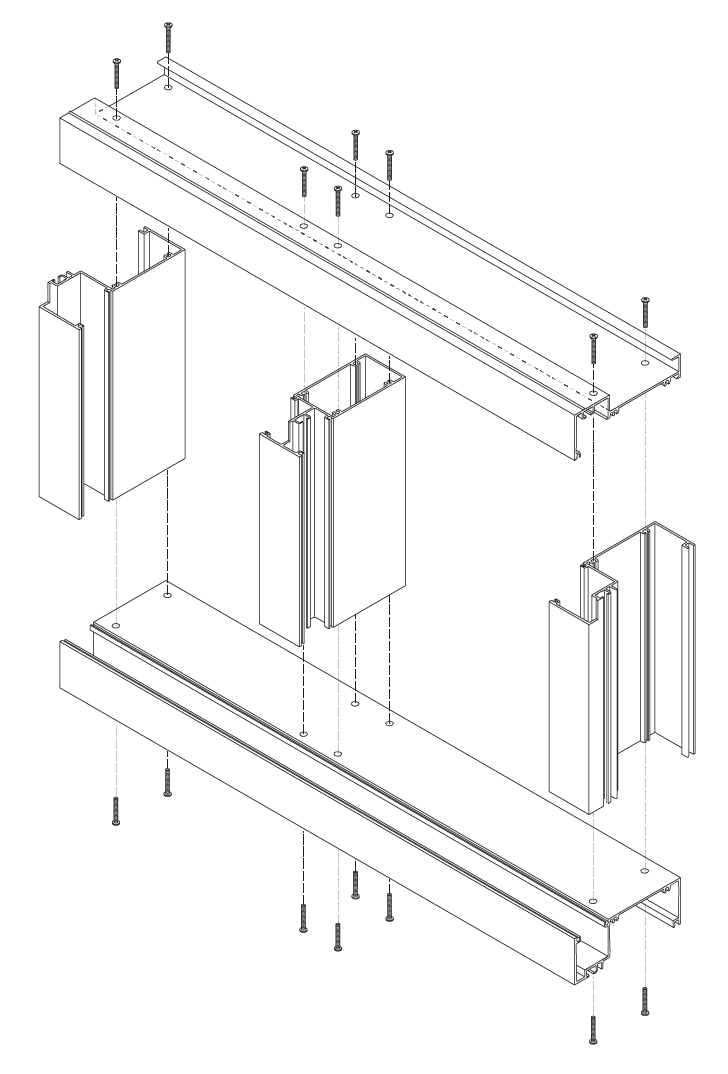

- PG 123® Framing may be supplied in stock lengths or factory fabricated

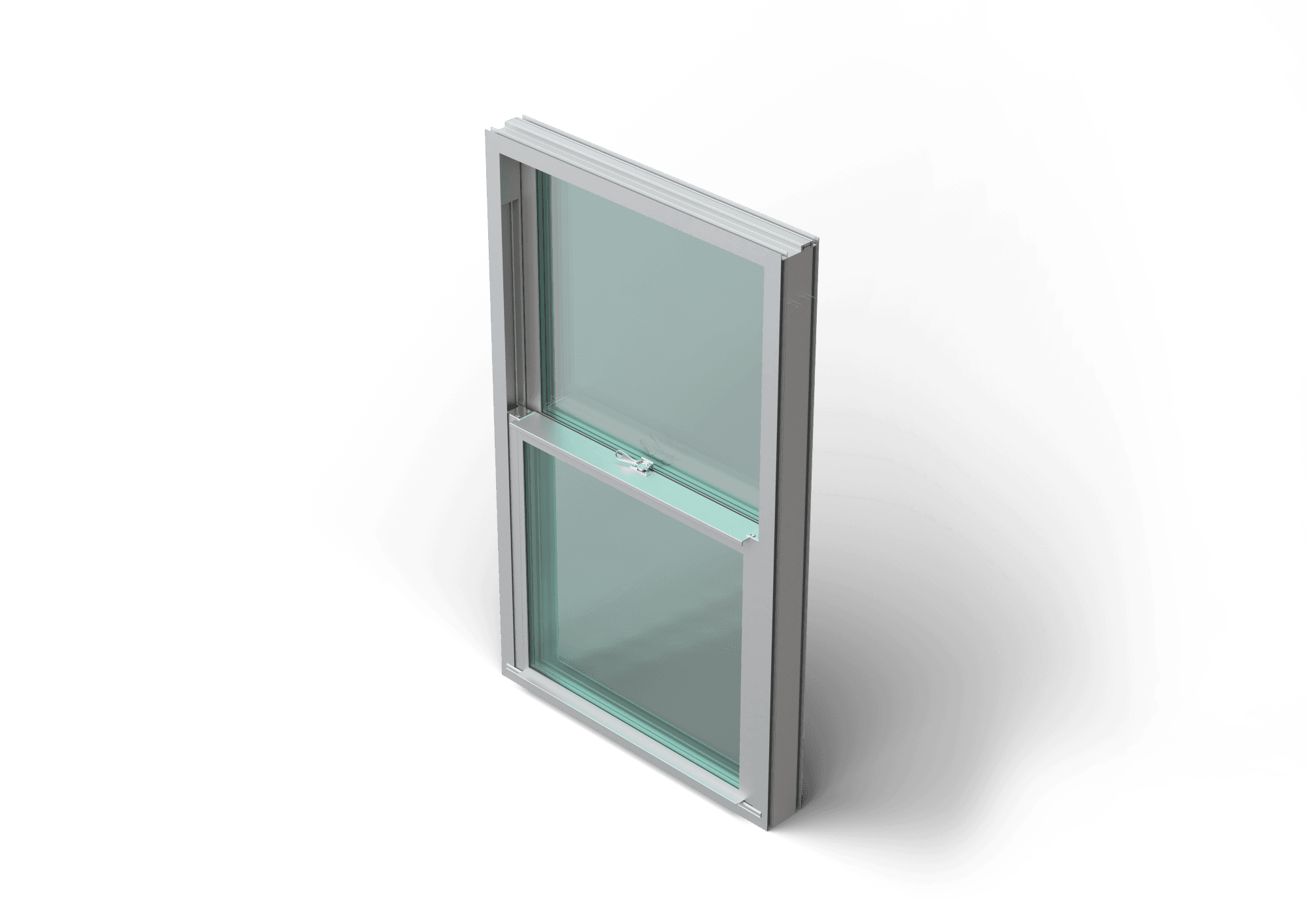

- The system can be pre-assembled and pre-glazed under controlled shop conditions that save time compared to field construction

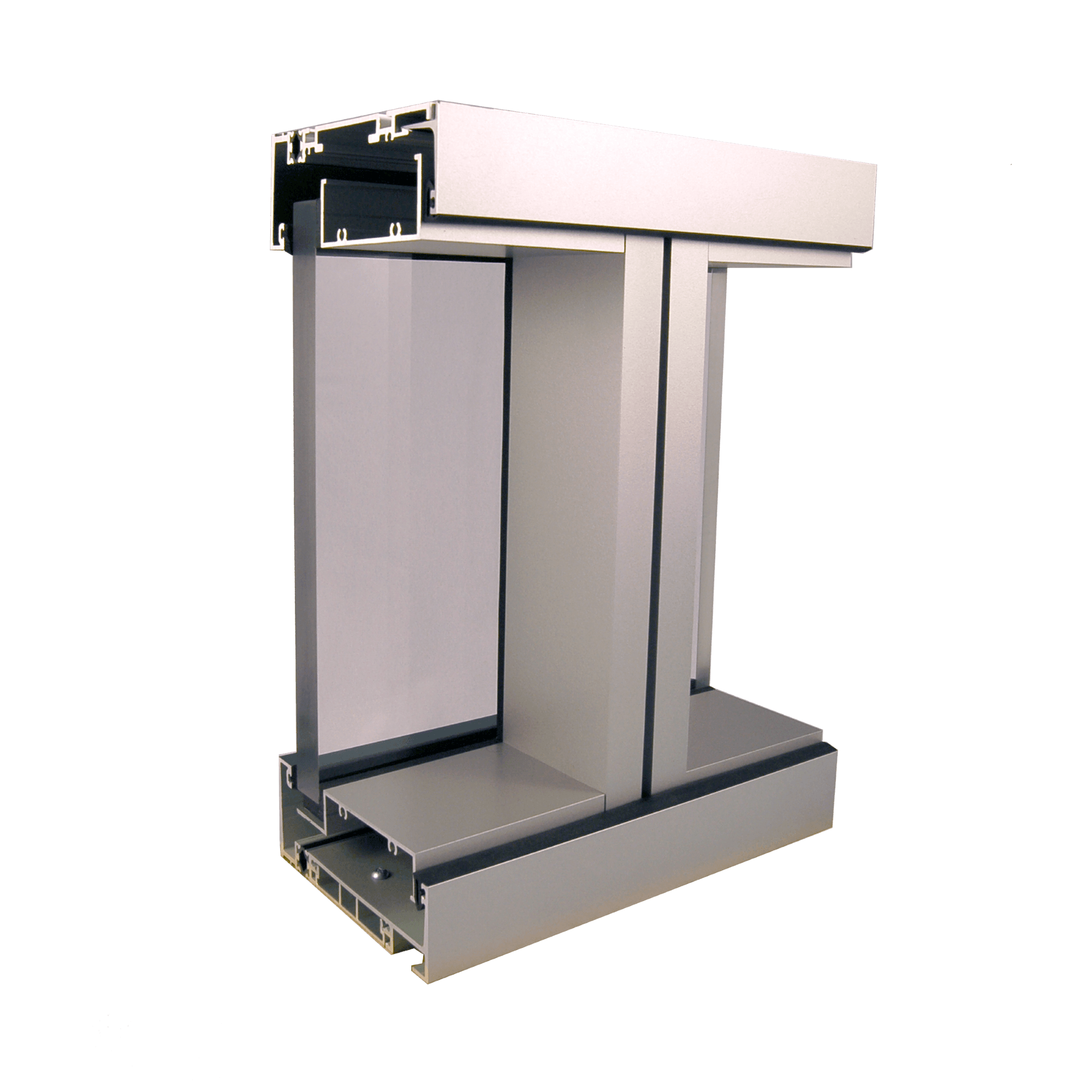

- Screw spline joinery, with square cuts and no miters or notching, reduce fabrication time

- Pre-glazed units are installed from the interior of the building to minimize weather delays and reduce the need for scaffolding and lift equipment

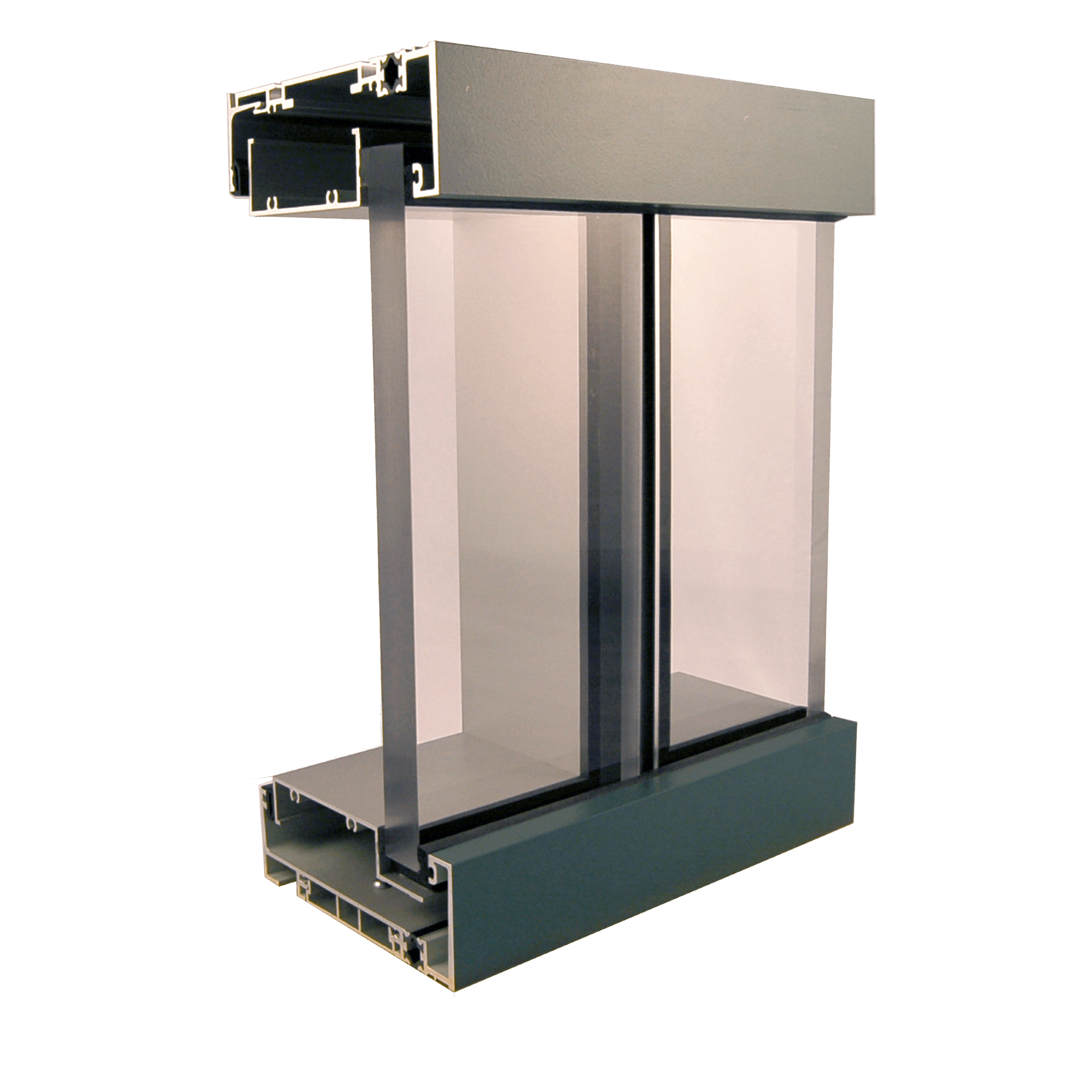

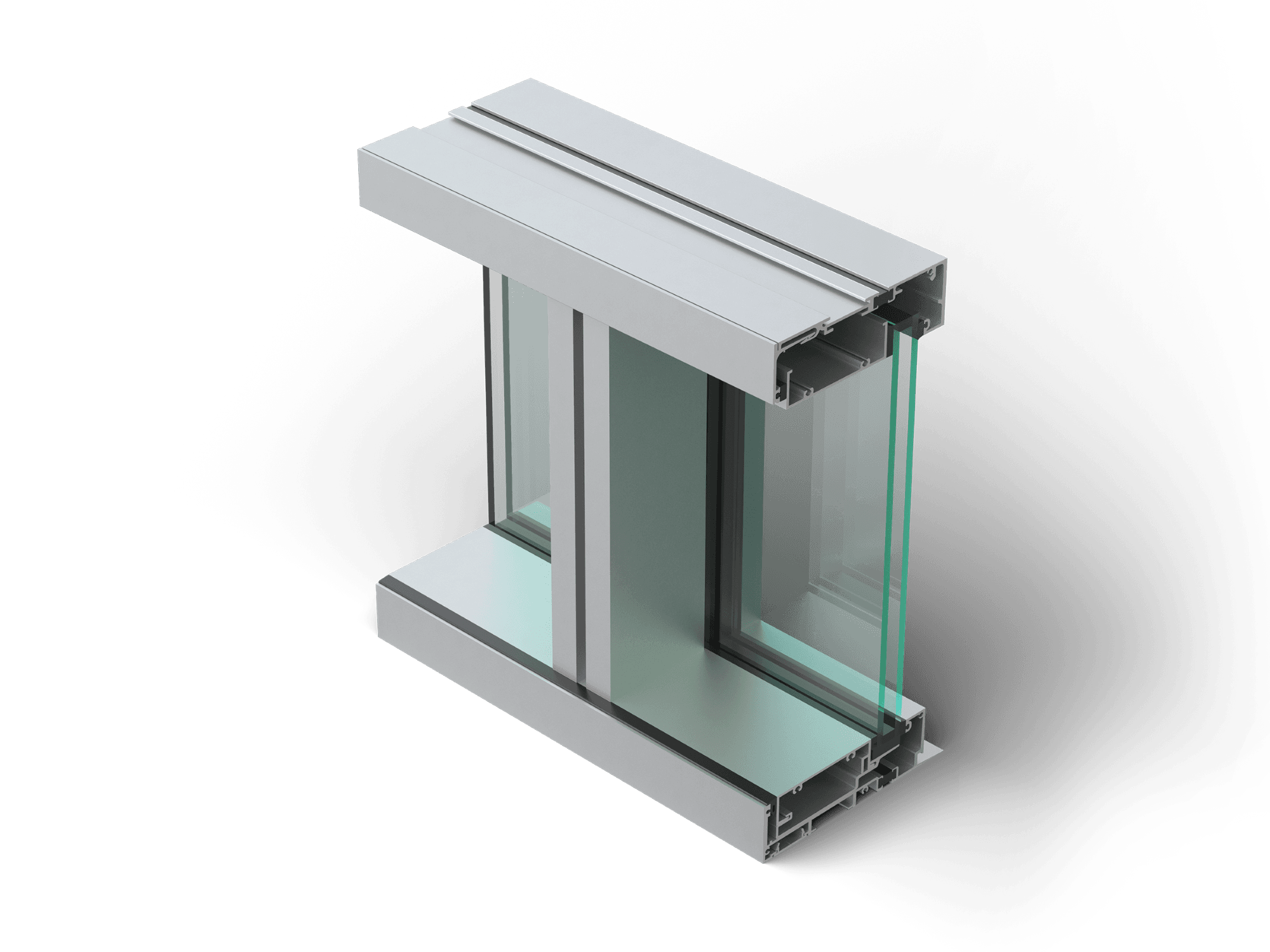

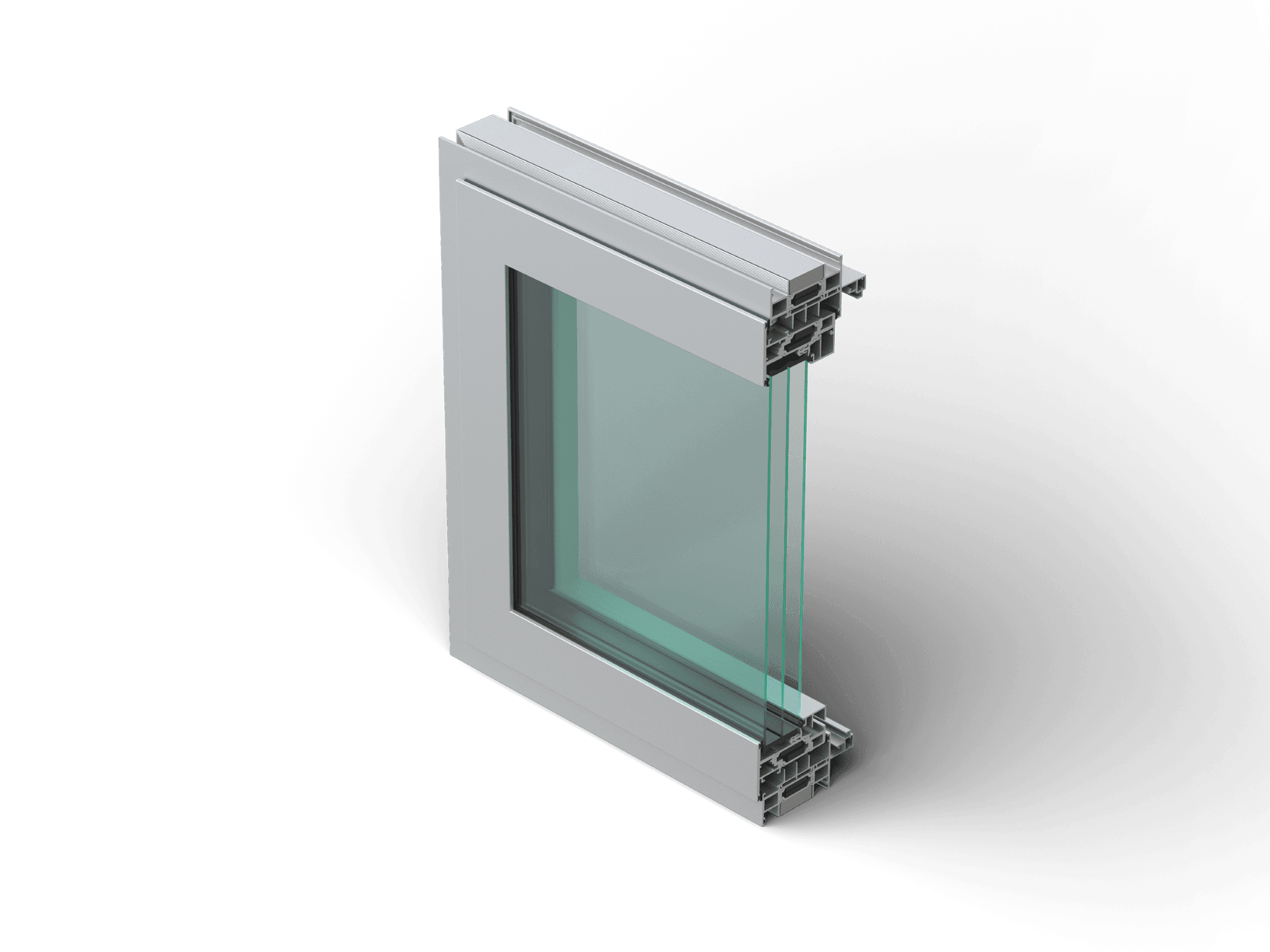

- Incorporates the IsoWeb® glass-reinforced nylon thermal break that provides improved condensation resistance and reduces thermal transmittance

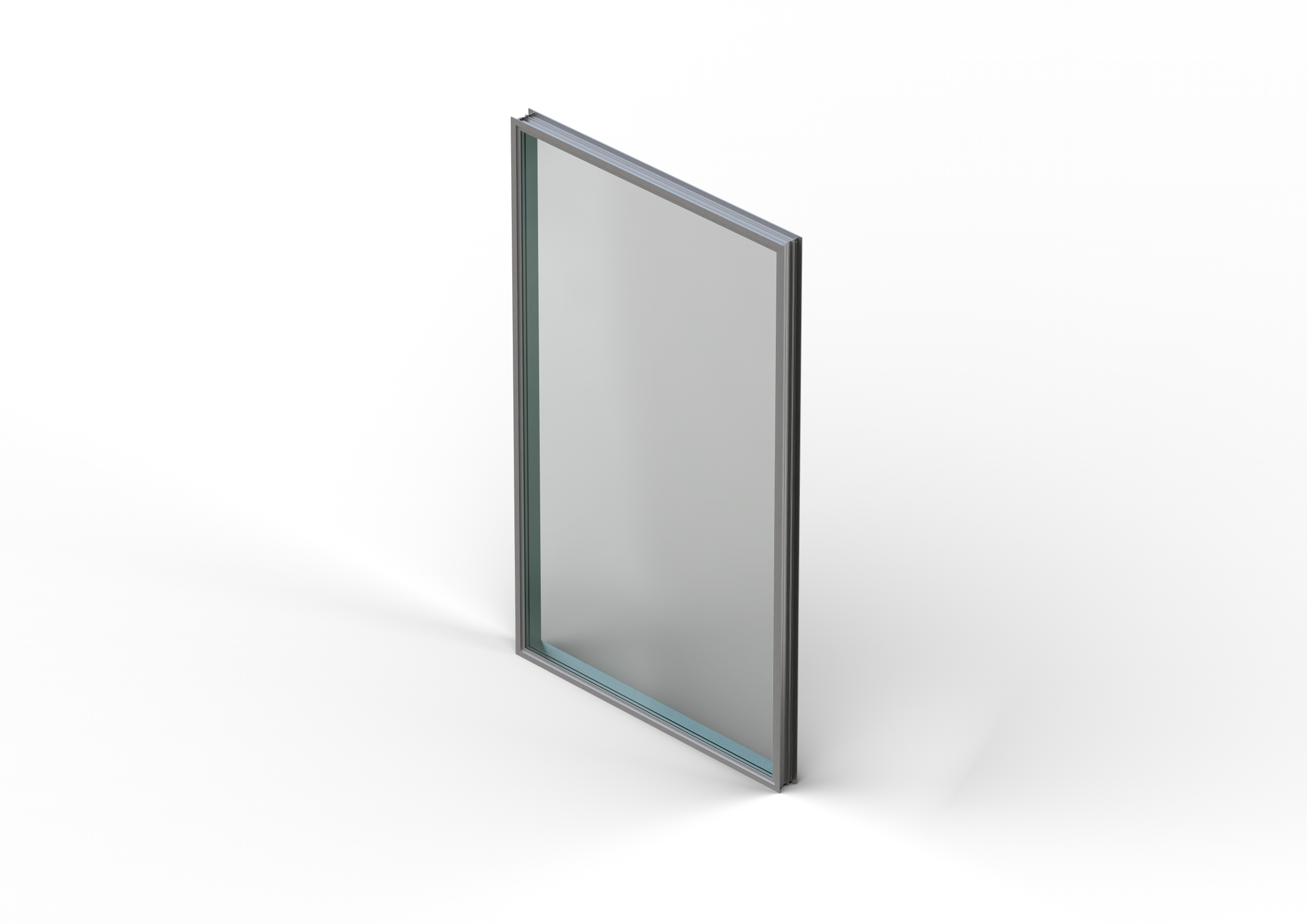

- Fully pressure equalized with a rain screen gasket to eliminate the exterior seal between glazed units

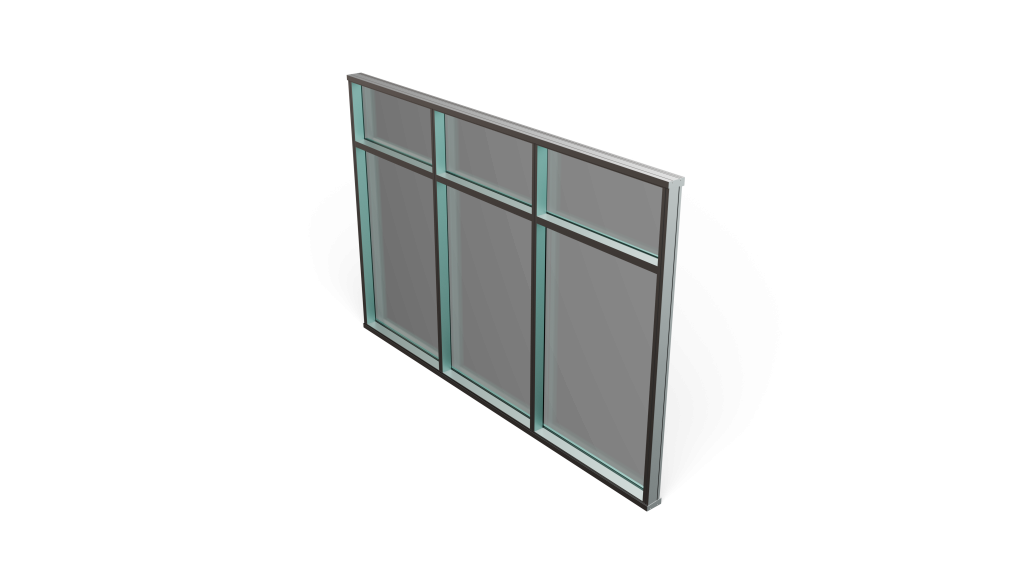

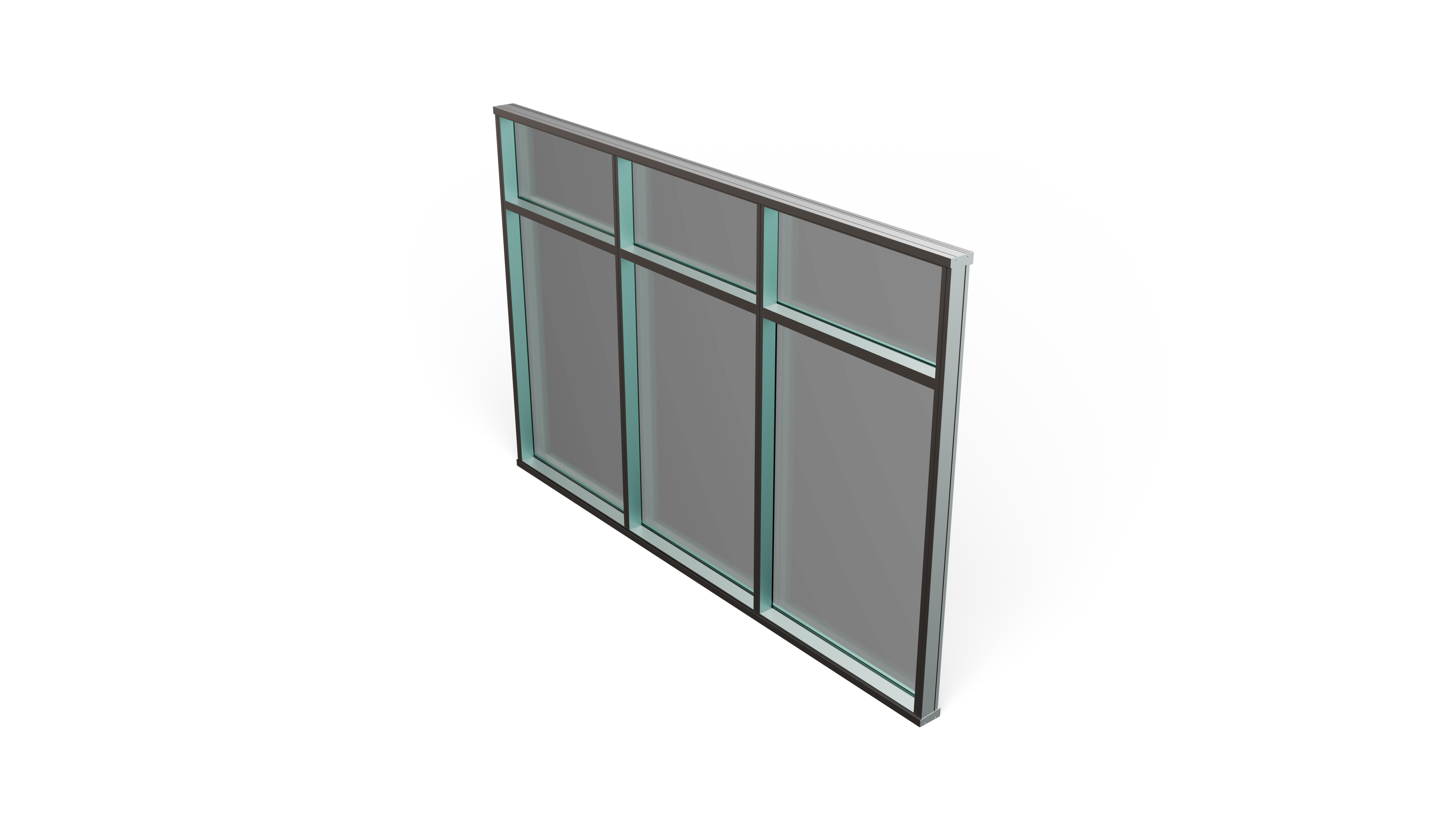

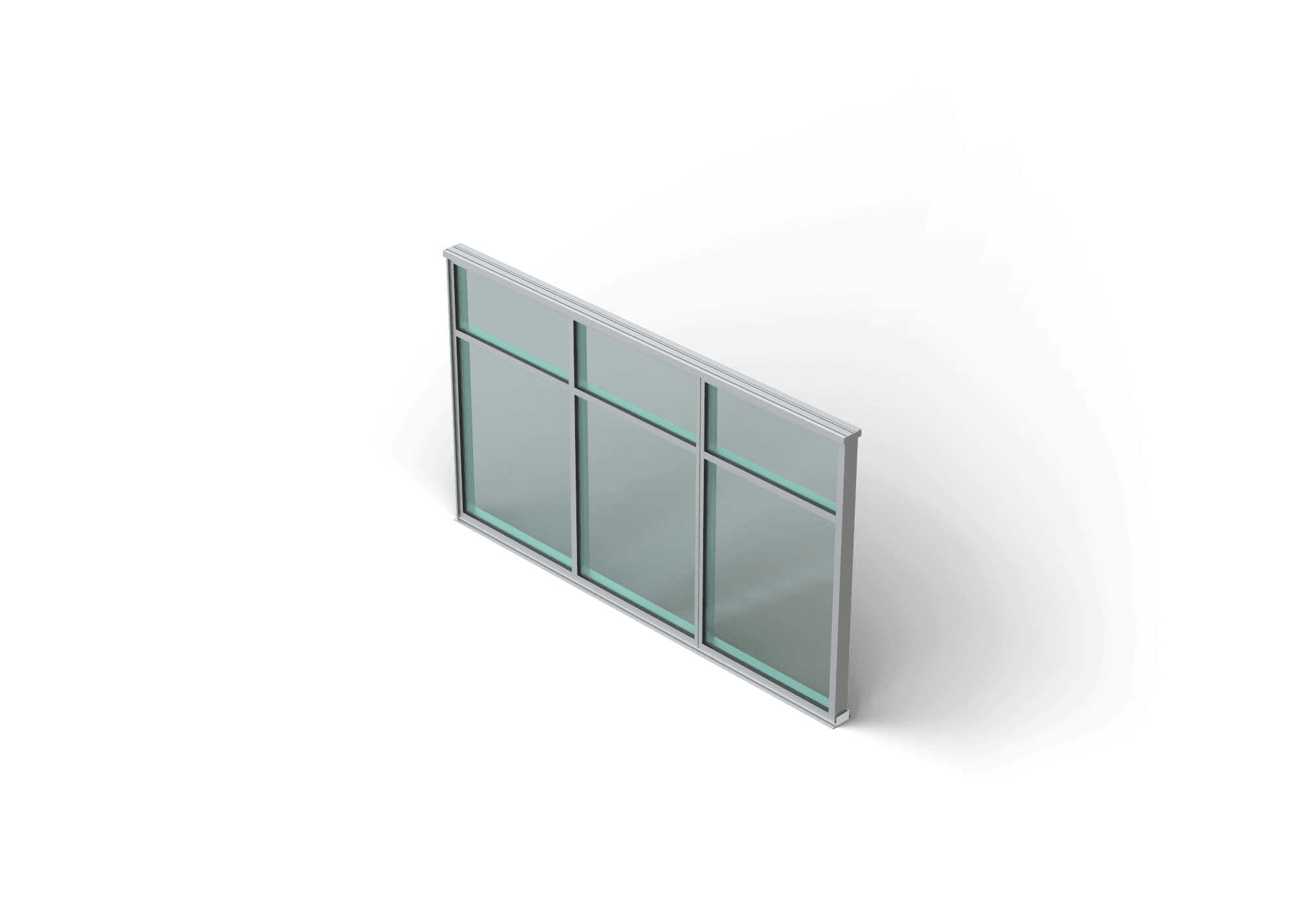

- Ribbon window wall application option available

- PG 123® Framing is fully tested to appropriate AAMA, ASTM & CAN/CSA A-440 standards for air, water and structural performance

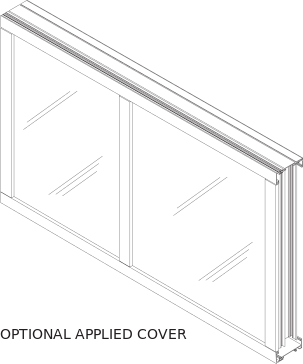

- The ribbon window system is structural silicone glazed vertically with optional applied covers to give a four-sided, captured appearance

- Optional vertical covers provide a clean, monumental appearance without sight line build up for building owners who prefer more traditional aesthetics

- The IsoWeb® Thermal Break offers dual finish options, allowing different interior and exterior color finishes

- Accommodates a one-inch infill with ¼” (6.4mm) adaptors for spandrel applications

- +/- 1/2″ (12.7) live load deflection

Optional Features

- 1/4″ infill adapter at spandrel area

- Corner mullions

- Steel reinforcing

- Profit$Maker® Plus die sets

Thermal Technology

Find out more here.

PG 123® Framing - Architectural Detail Manual

2 MB

PG 123® Framing - Flyer

423 KB

Window Wall/Aluminum Window Wall Systems - EPD

866 KB

Finishes Information - Architectural Detail Manual

238 KB

Anodize Finishes - Color Chart

82 KB

Liquid Paint - Color Chart - Permadize®

1 MB

Liquid Paint - Color Chart - Permafluor®

350 KB

PG 123® Framing - English

Typical Details (Weatherseal Glazing)

Typical Details (Reinforced Weatherseal Glazing)

Typical Details (Captured Glazing with Covers)

Typical Details (Reinforced Captured Glazing with Covers)

Anchor and Splice Details

While most of our products are not hazardous in and amongst themselves, hazardous properties can develop when the product is altered through cutting, welding, and grinding. Details on the specific hazards that can develop and the proper protective measures to use can be found in the SDSs.

Arconic’s SDS database provides PDF files of safety information on specific materials. The SDS ID numbers (product code) and description for materials used in Kawneer products are listed below.

SDS # DESCRIPTION / TITLE

1405 – Kawneer Thermal Break Filled Extrusions

1385 – Kawneer Acrylic Paints

1386 – Kawneer Fluoropolymer Paints

1526 – Kawneer Bloomsburg Solvent Recovery Still Residuals

1387 – Painted Architectural Aluminum Extrusions

509 – Aluminum Extrusions, Anodized Aluminum Products

Search Arconic’s SDS database for safety information on specific materials.

Search Instructions

Project Warranty Cover Sheet (English)

137 KB

Project Warranty Cover Sheet (French-Canadian)

137 KB

Project Warranty Cover Sheet Sample (English)

139 KB

Project Warranty Cover Sheet Sample (French-Canadian)

140 KB

Material & Workmanship - English

185 KB

Material & Workmanship - French

190 KB

Material & Workmanship Sample (English)

203 KB

Material & Workmanship Sample (French Canadian)

212 KB

Anodized Finishes Warranty - English

523 KB

Anodized Finishes Warranty - French

517 KB

Anodized Finishes Sample (English)

529 KB

Anodized Finishes Sample (French Canadian)

524 KB

Painted Finishes Warranty - English

557 KB

Painted Finishes Warranty - French

538 KB

Painted Finishes Sample (English)

565 KB

Painted Finishes Sample (French Canadian)

550 KB

Insulating Glass Warranty - English

498 KB

Insulating Glass Warranty - French

499 KB

Insulating Glass Sample (English)

502 KB

Insulating Glass Sample (French Canadian)

504 KB

Laminated Glass Warranty - English

122 KB

Laminated Glass Warranty - French

123 KB

Laminated Glass Sample (English)

126 KB

Laminated Glass Sample (French Canadian)

128 KB

Corrective Field Repairs (English)

154 KB

Corrective Field Repairs (French-Canadian)

152 KB