IsoLock® Pour and Debridge Thermal Break

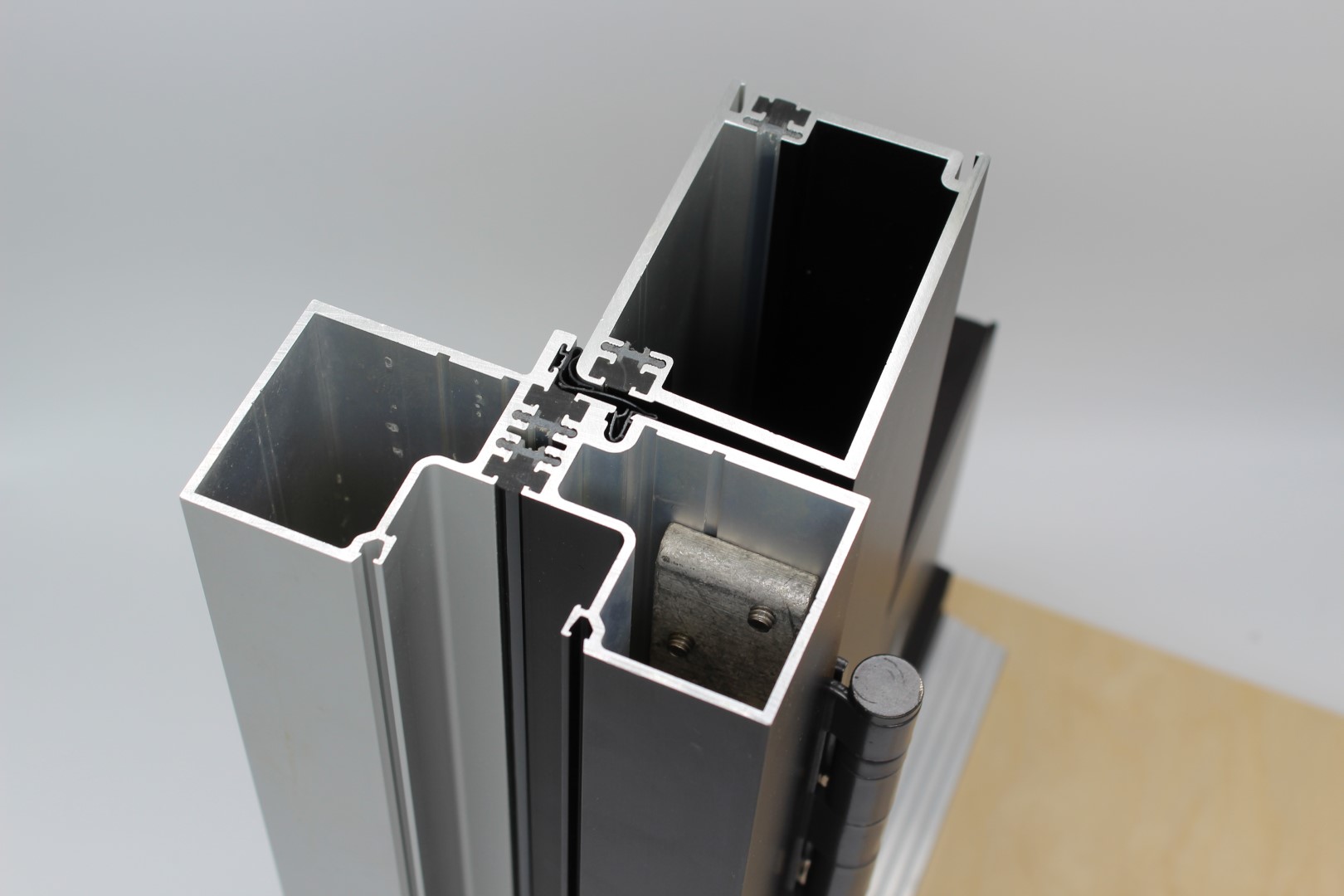

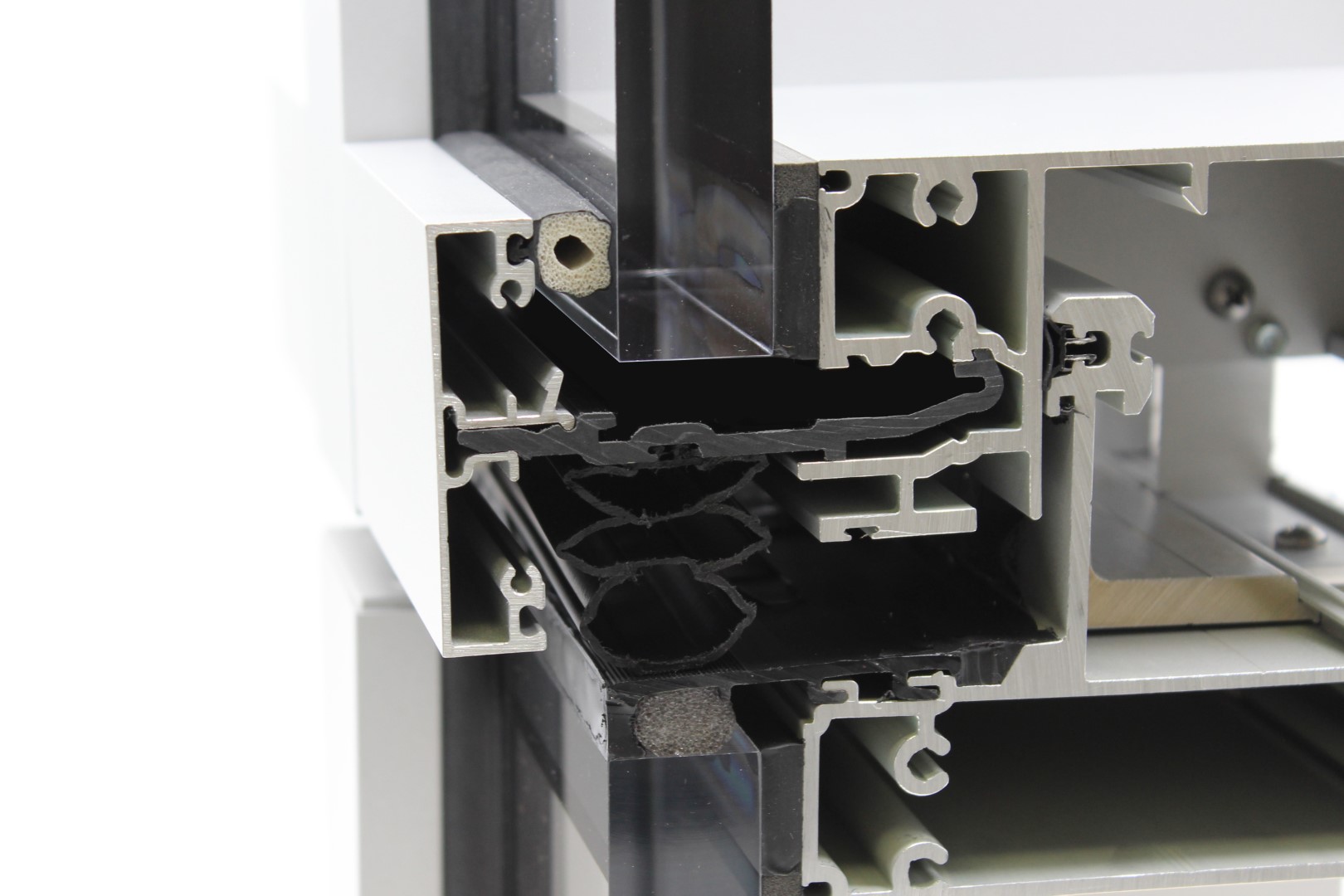

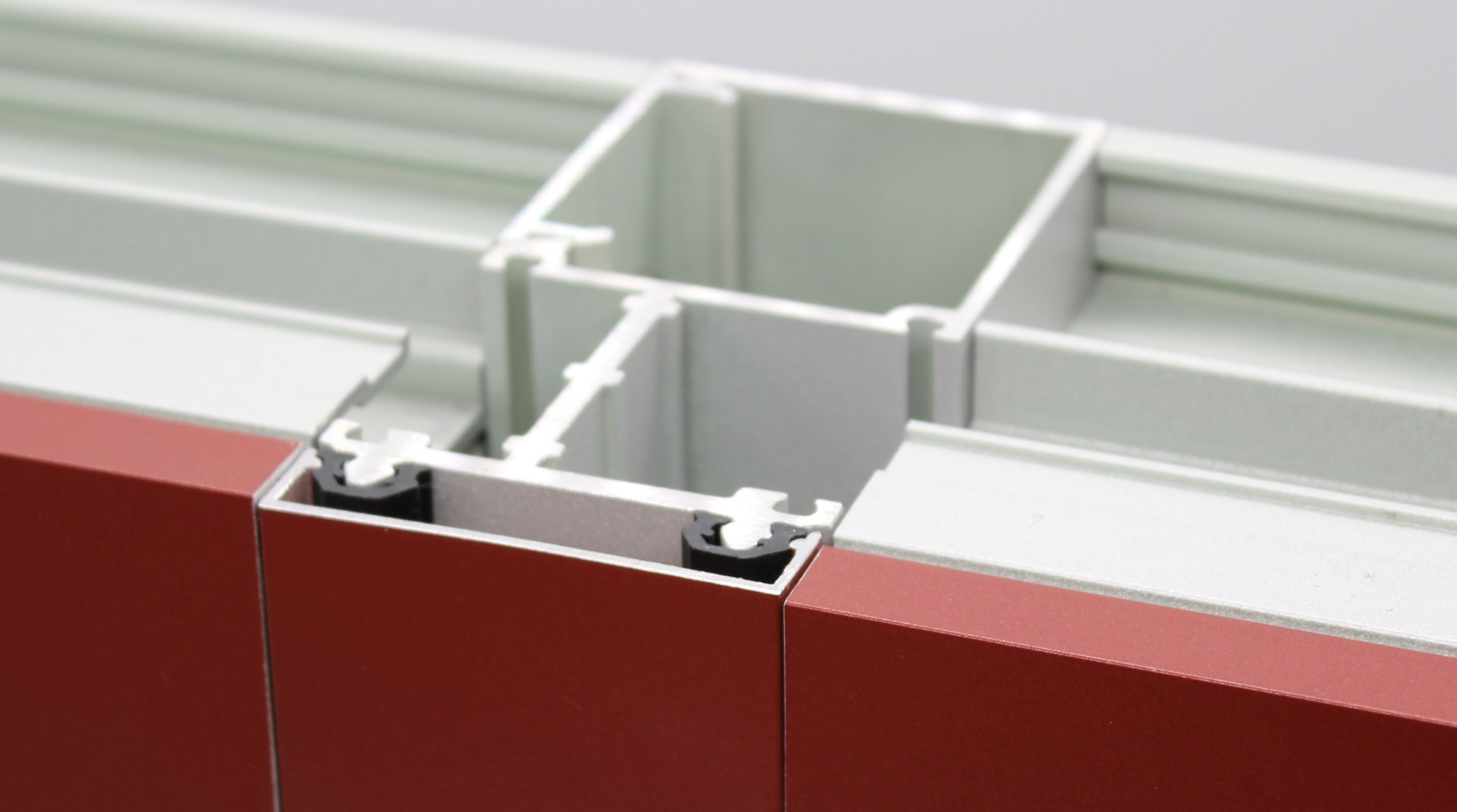

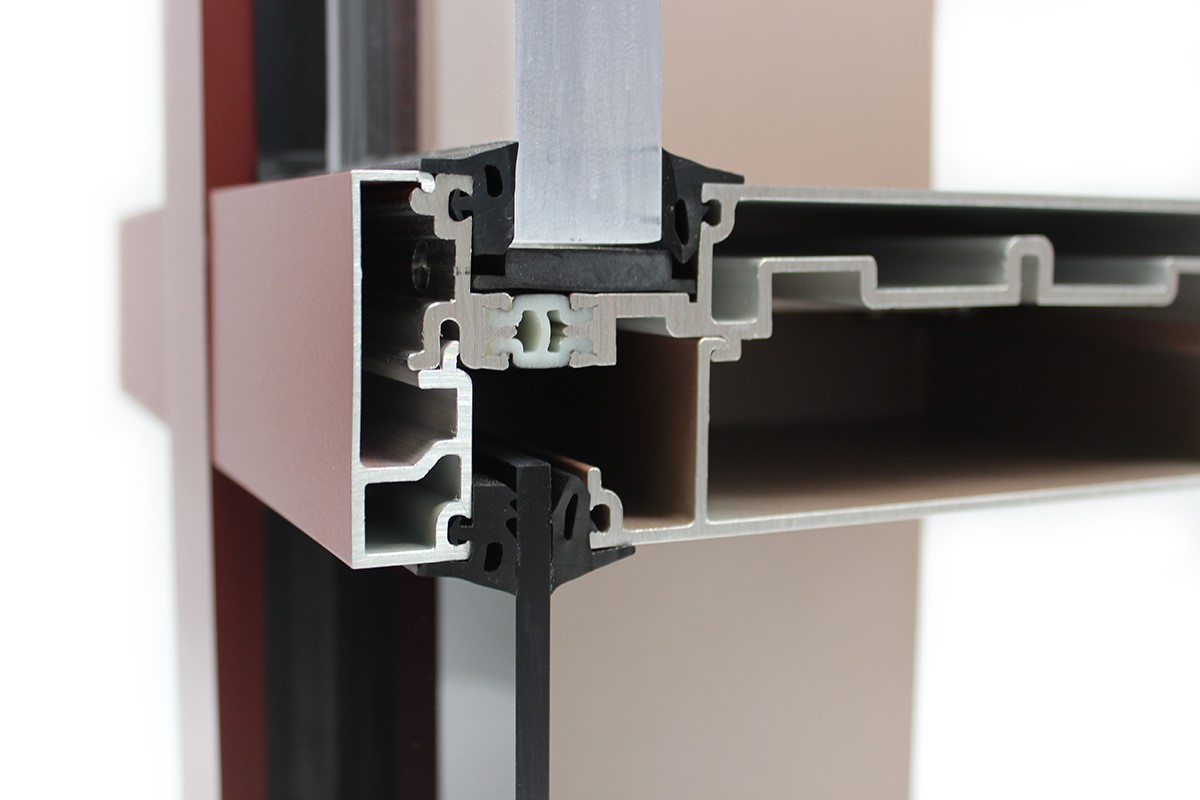

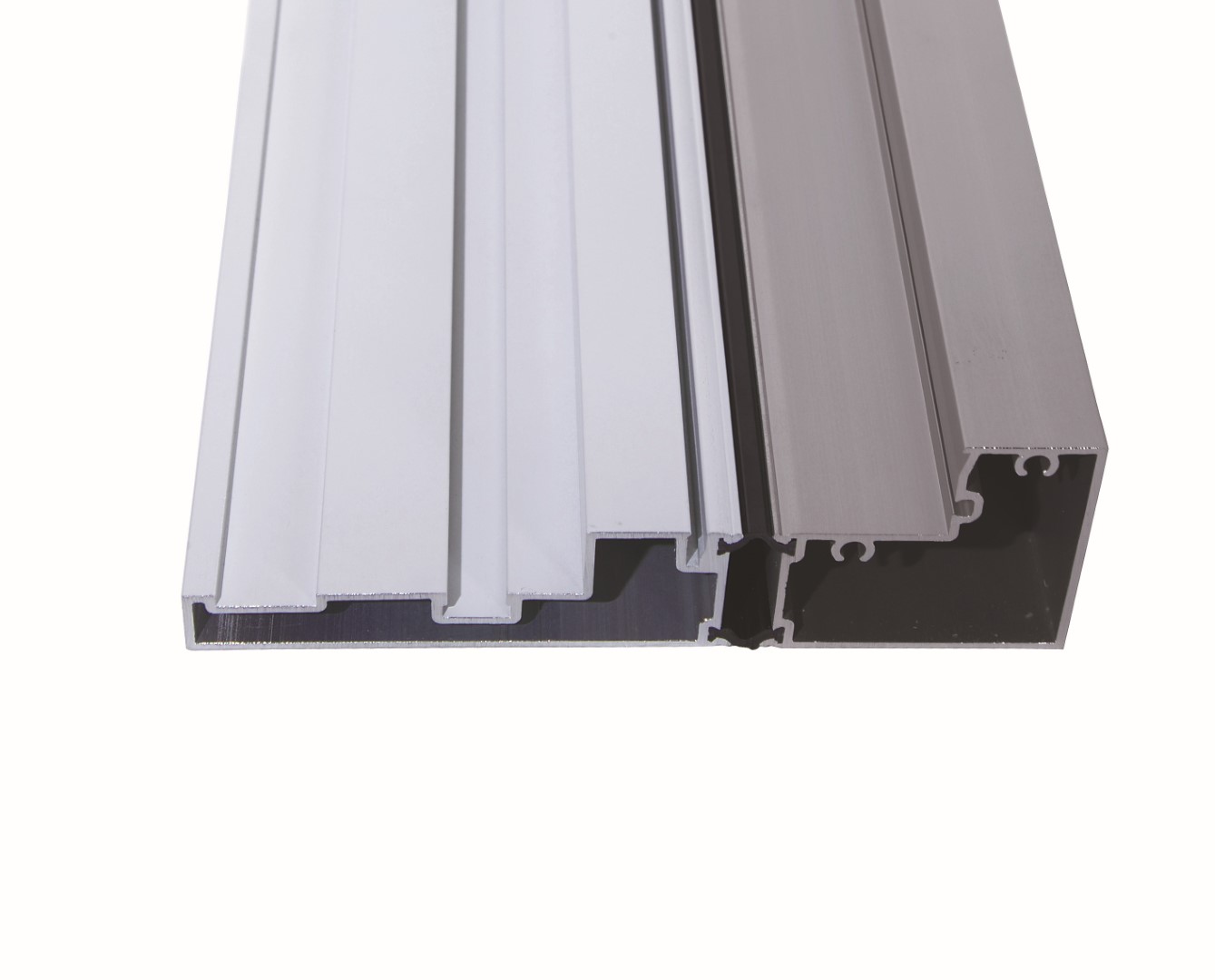

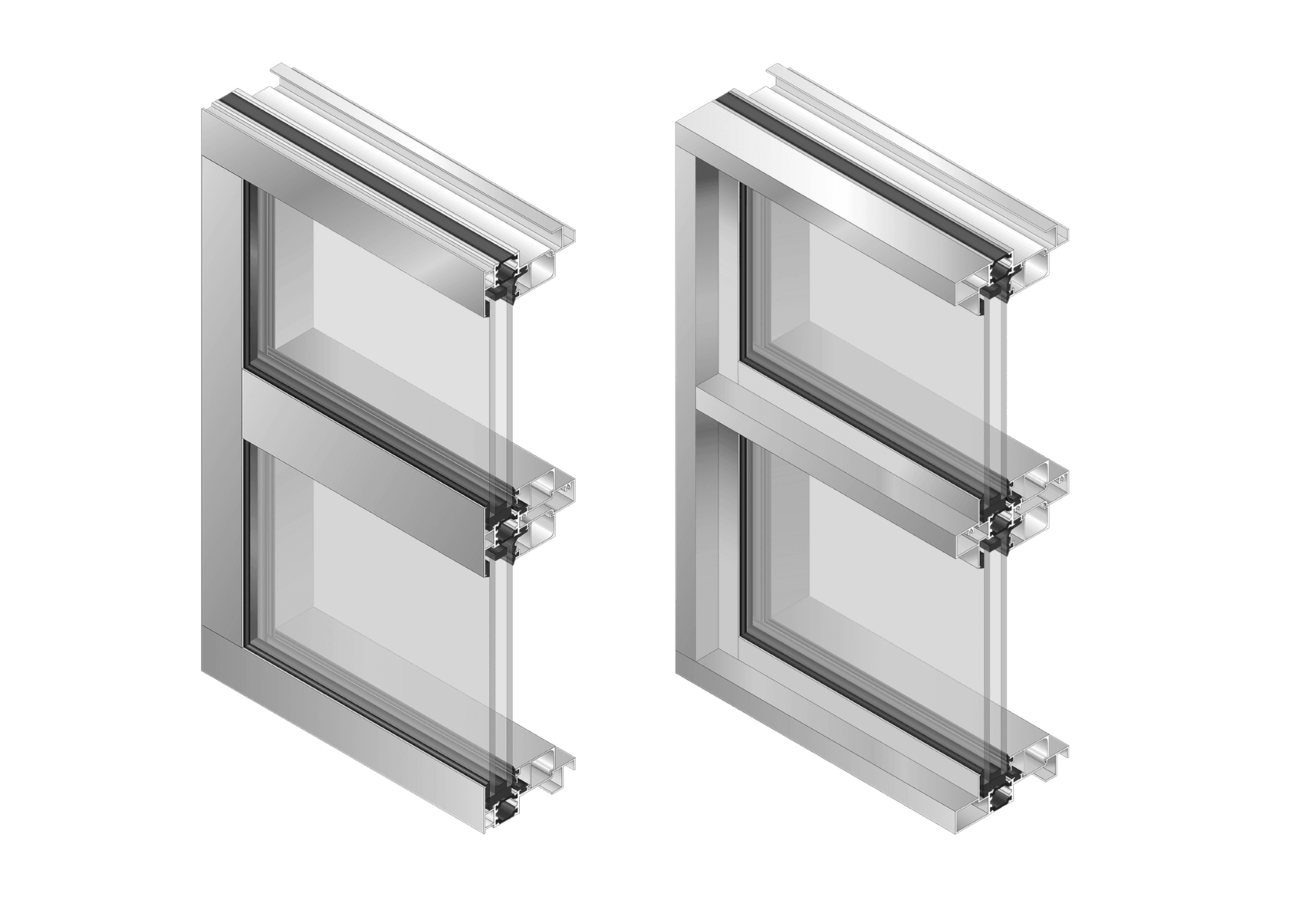

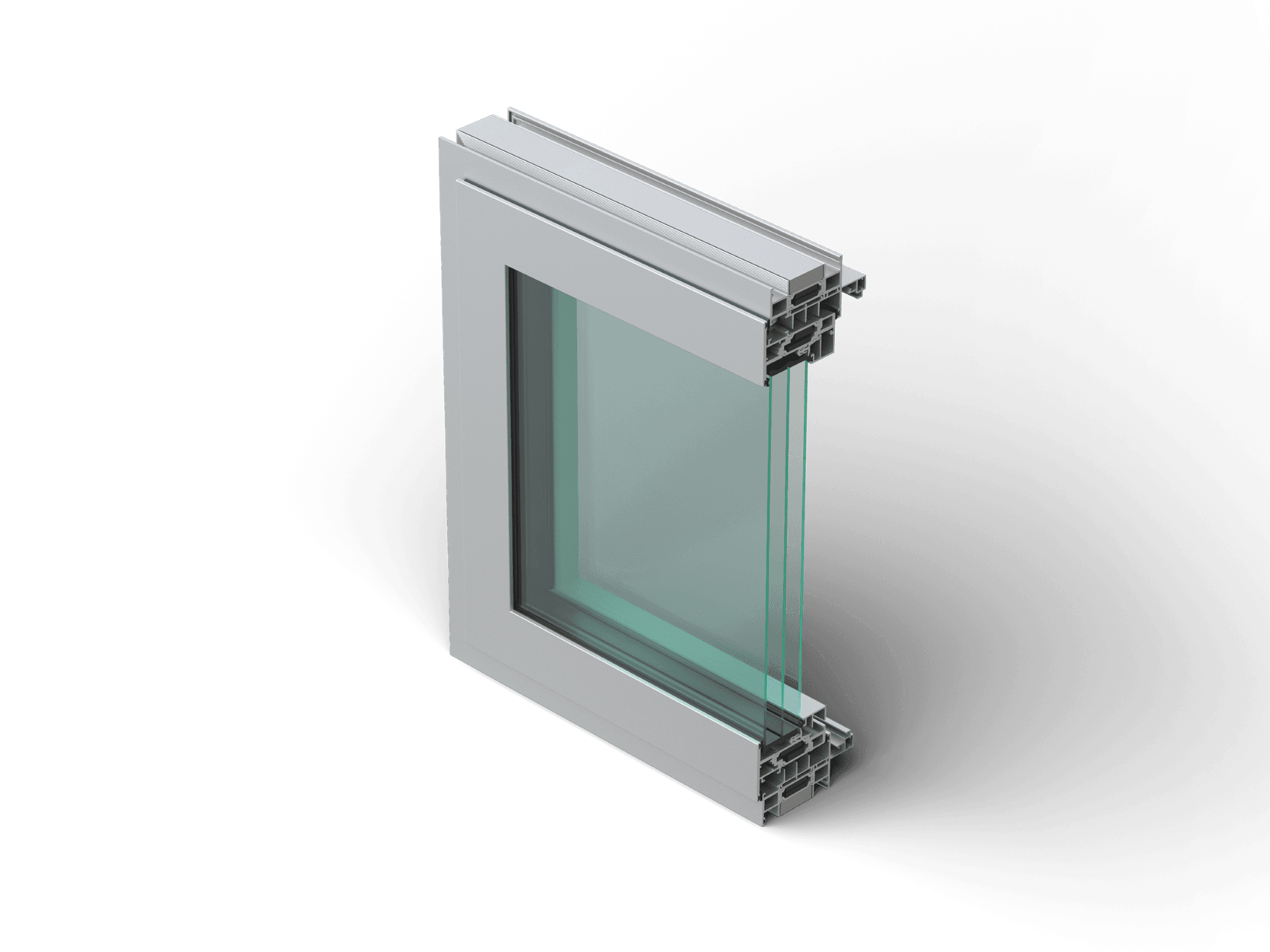

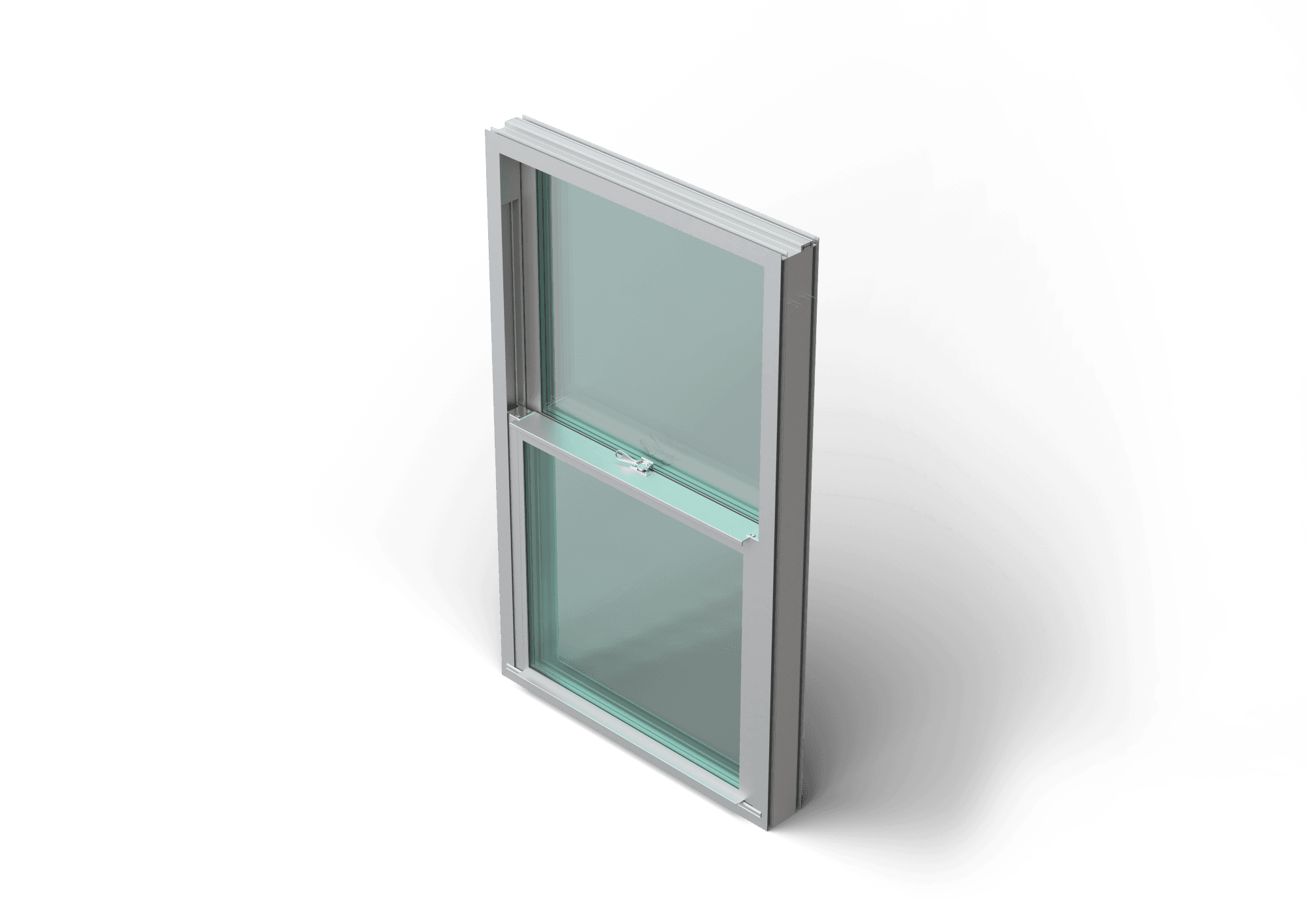

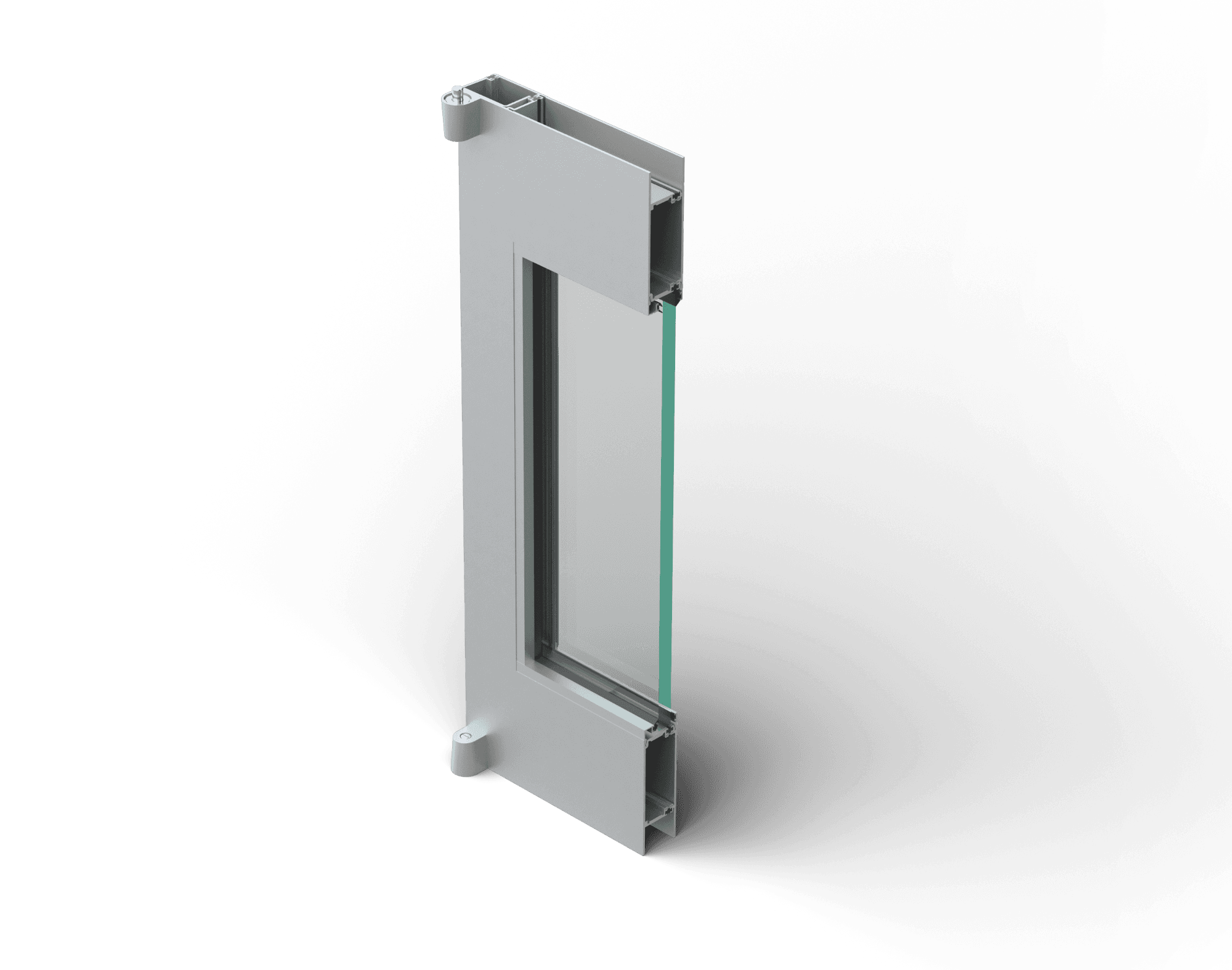

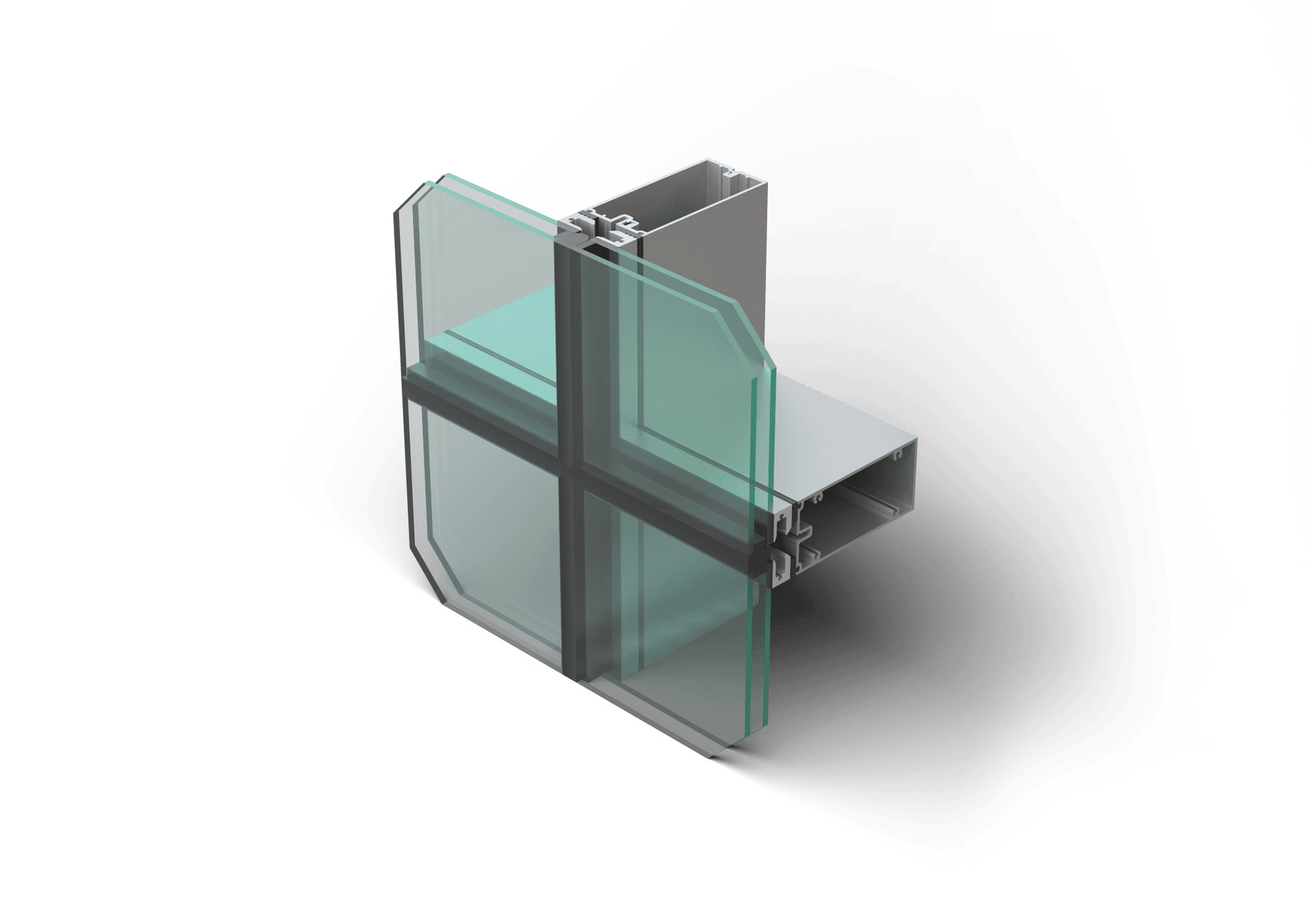

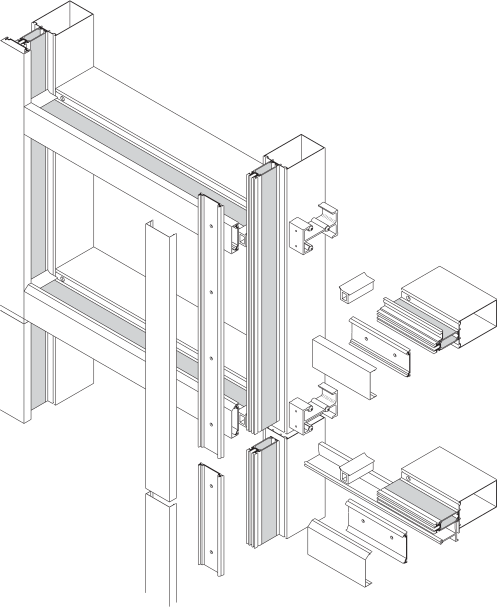

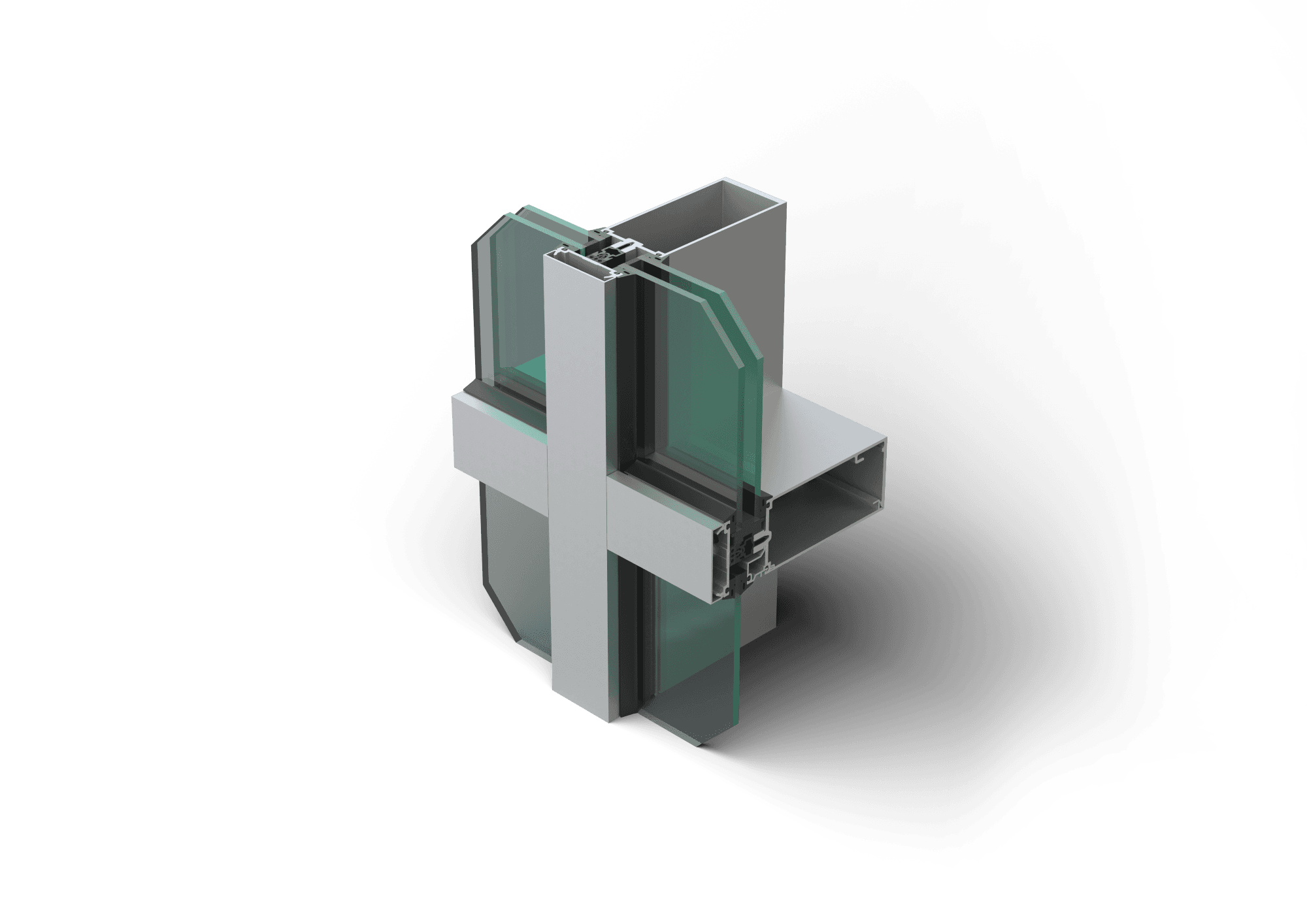

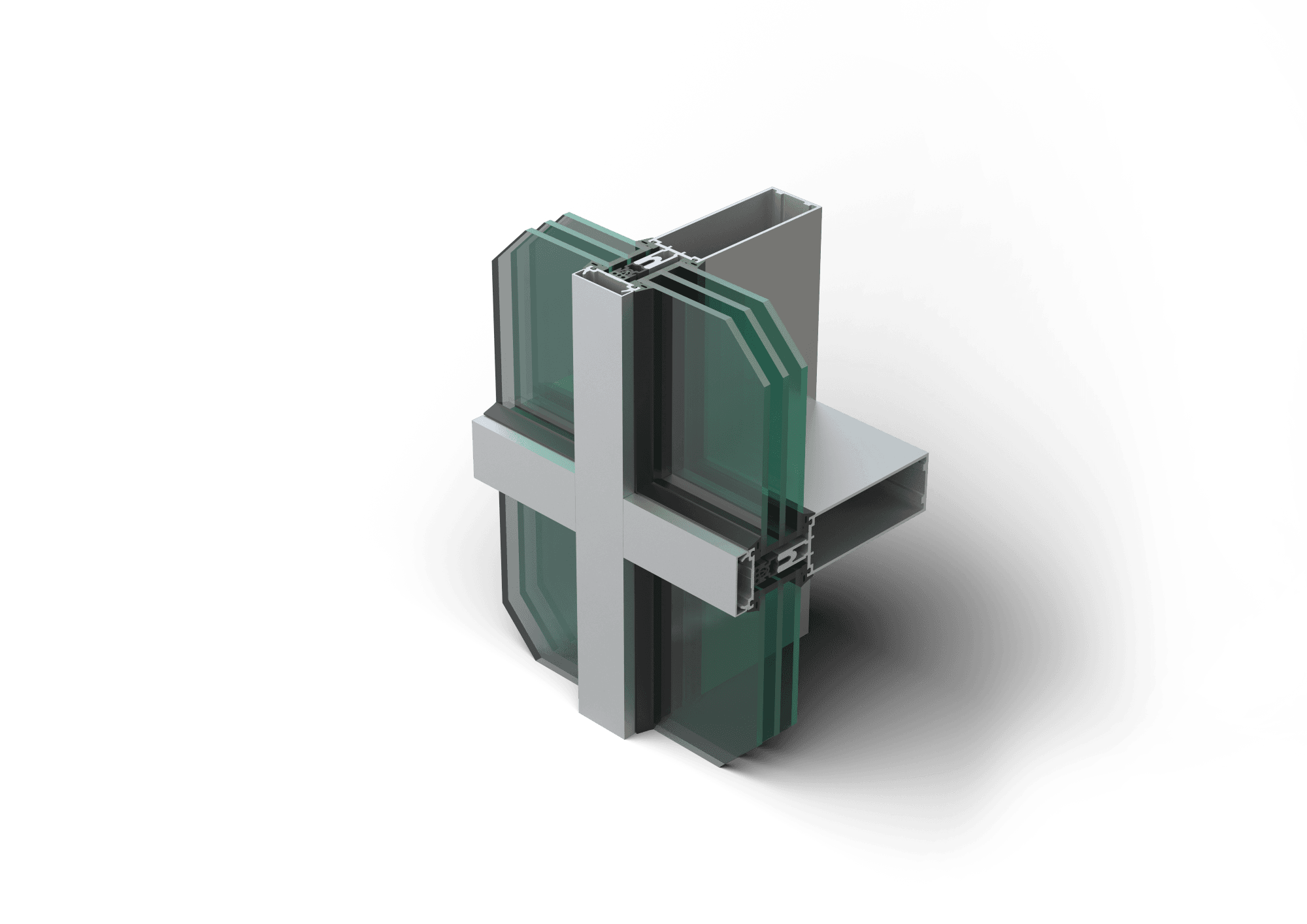

Pour and debridge (P&D) thermal breaks offer a cost-effective solution with superior thermal performance and a single-piece extrusion. Options are available in single and dual pocket designs.

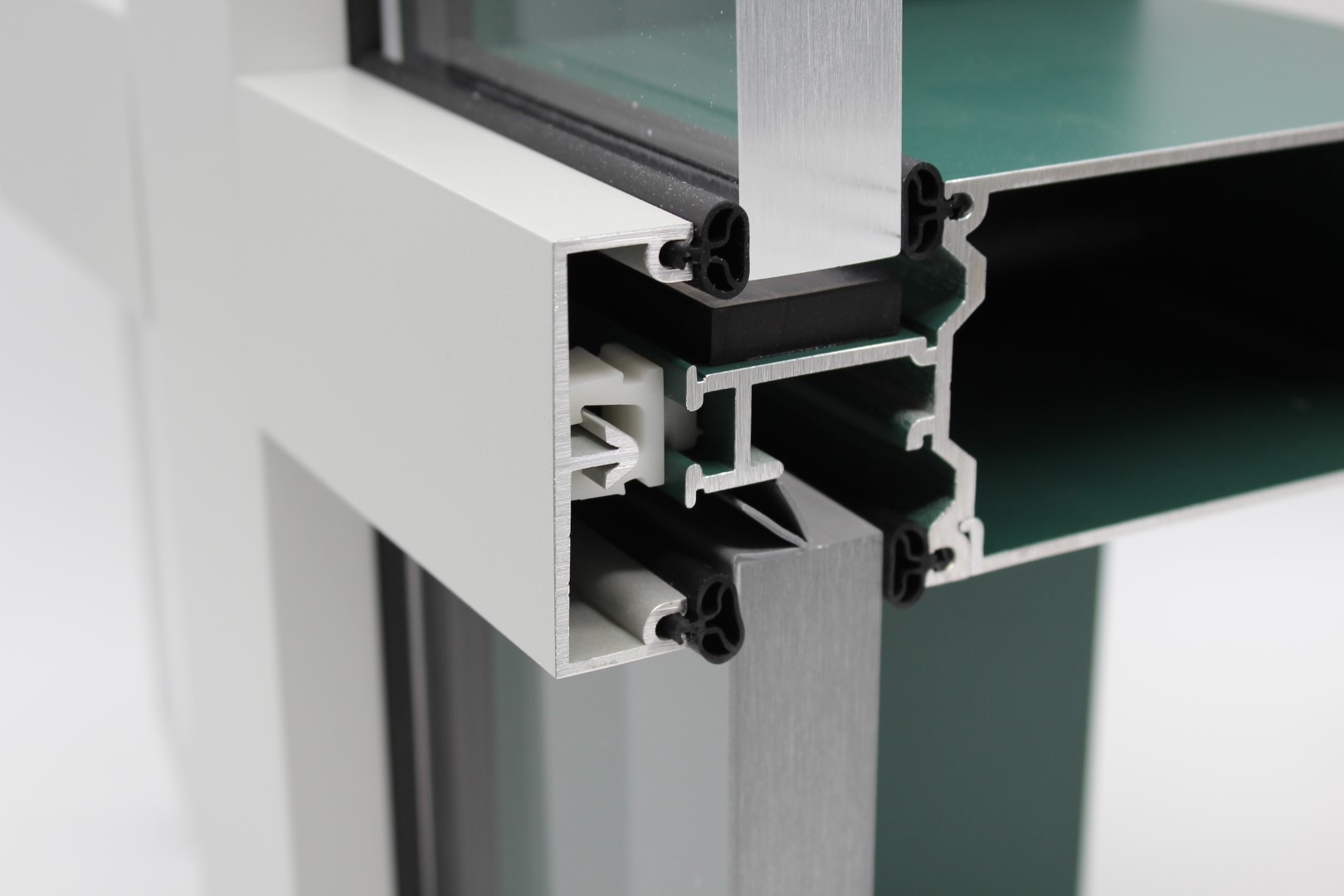

Factory-supplied P&D products involve pouring liquid urethane into a cavity or thermal pocket, allowing it to harden and cutting away a small section of aluminum opposite the pour area to fully separate the exterior aluminum from the interior aluminum. This thermal barrier enables to reduce labor and costs as there are fewer parts to cut and assemble.

Kawneer’s P&D thermal products utilize an IsoLock® process to eliminate expansion and contraction of urethane. The IsoLock® process can be achieved by one of two means. Prior to the pouring operation, the aluminum is either lanced into the cavity at increments of 1-1/2”, or the interior of the thermal pocket is abraded. The lanced or abraded surface creates a mechanical lock in the urethane before it hardens, eliminating any potential for shrinkage. The mechanical locks, combined with the adhesive bond of the urethane to the aluminum, creating a composite section used to meet design wind loads.

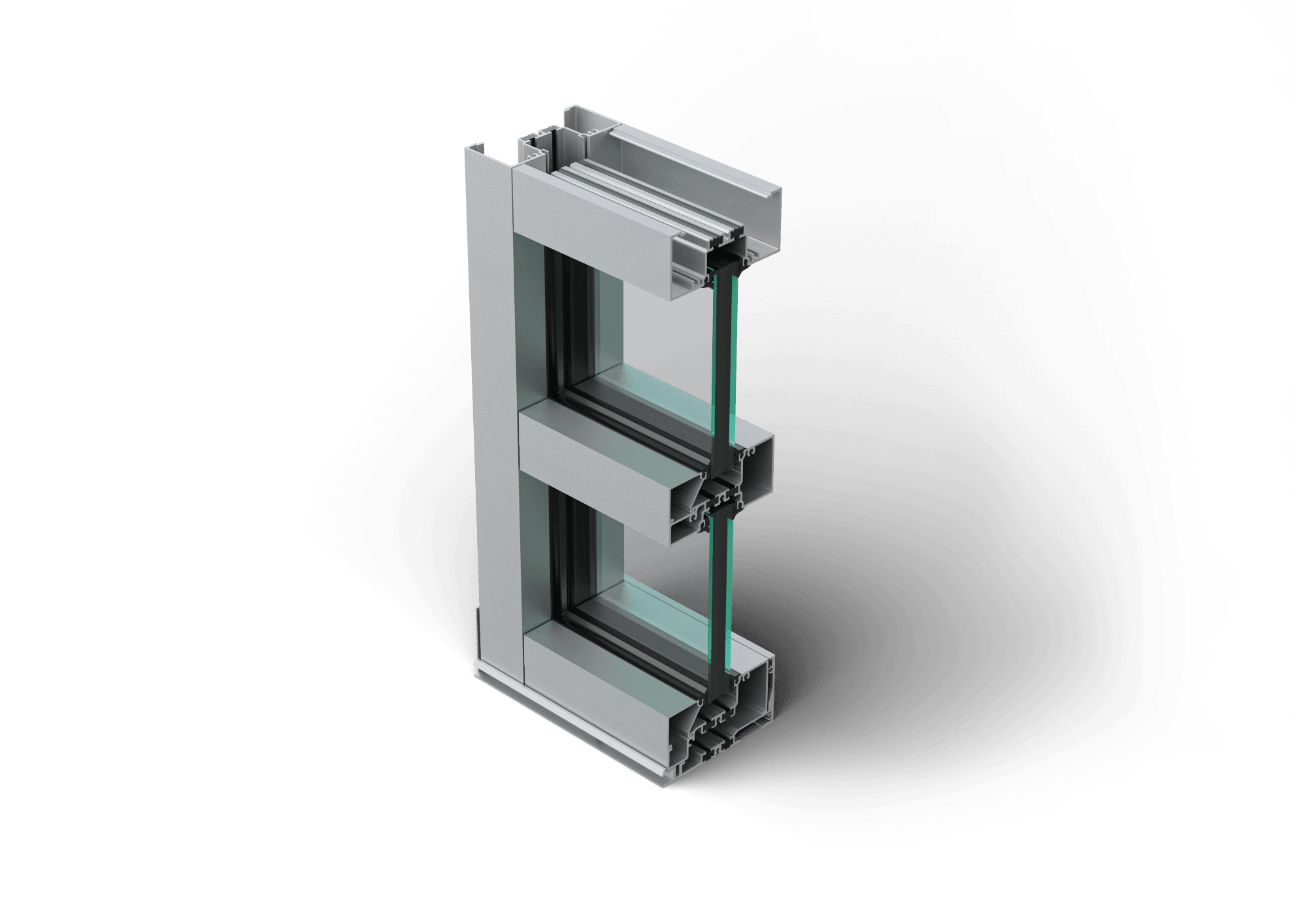

Related products:

Trifab® 451T Framing System, Trifab® 601T Framing System, IR 501T Framing System, 8400TL Thermal Windows, MetroView® FG 501T Window Wall

Related products with dual IsoLock® lanced pour and debridge thermal breaks:

Trifab® 451UT Framing System, Trifab® 601UT Framing System, IR 501UT Framing System

Download Brochure

Download Brochure