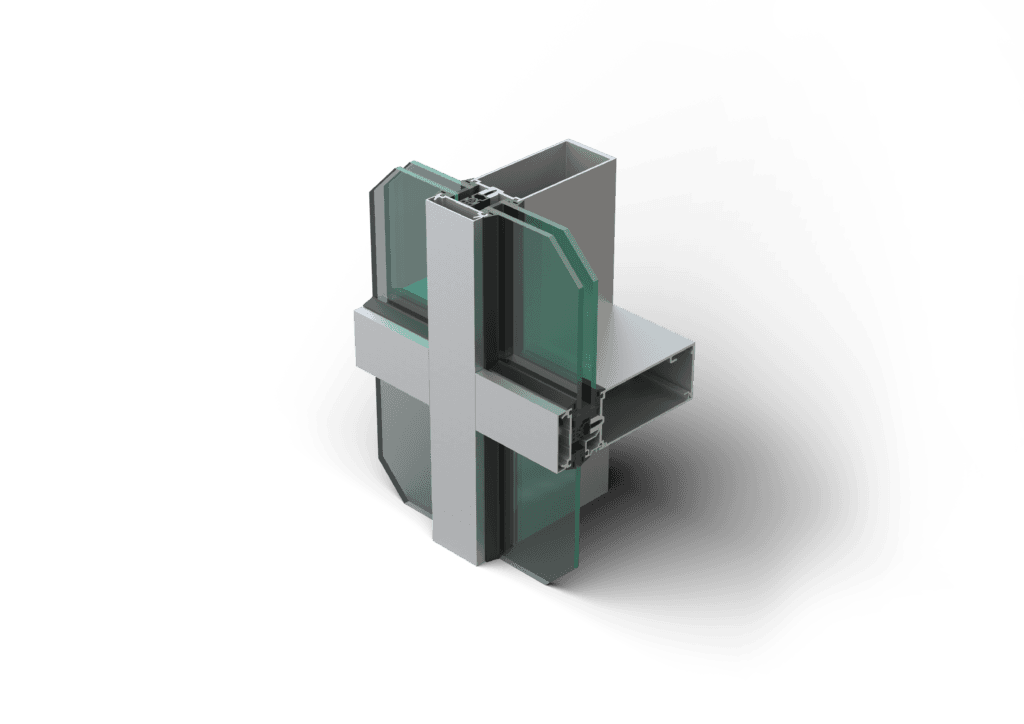

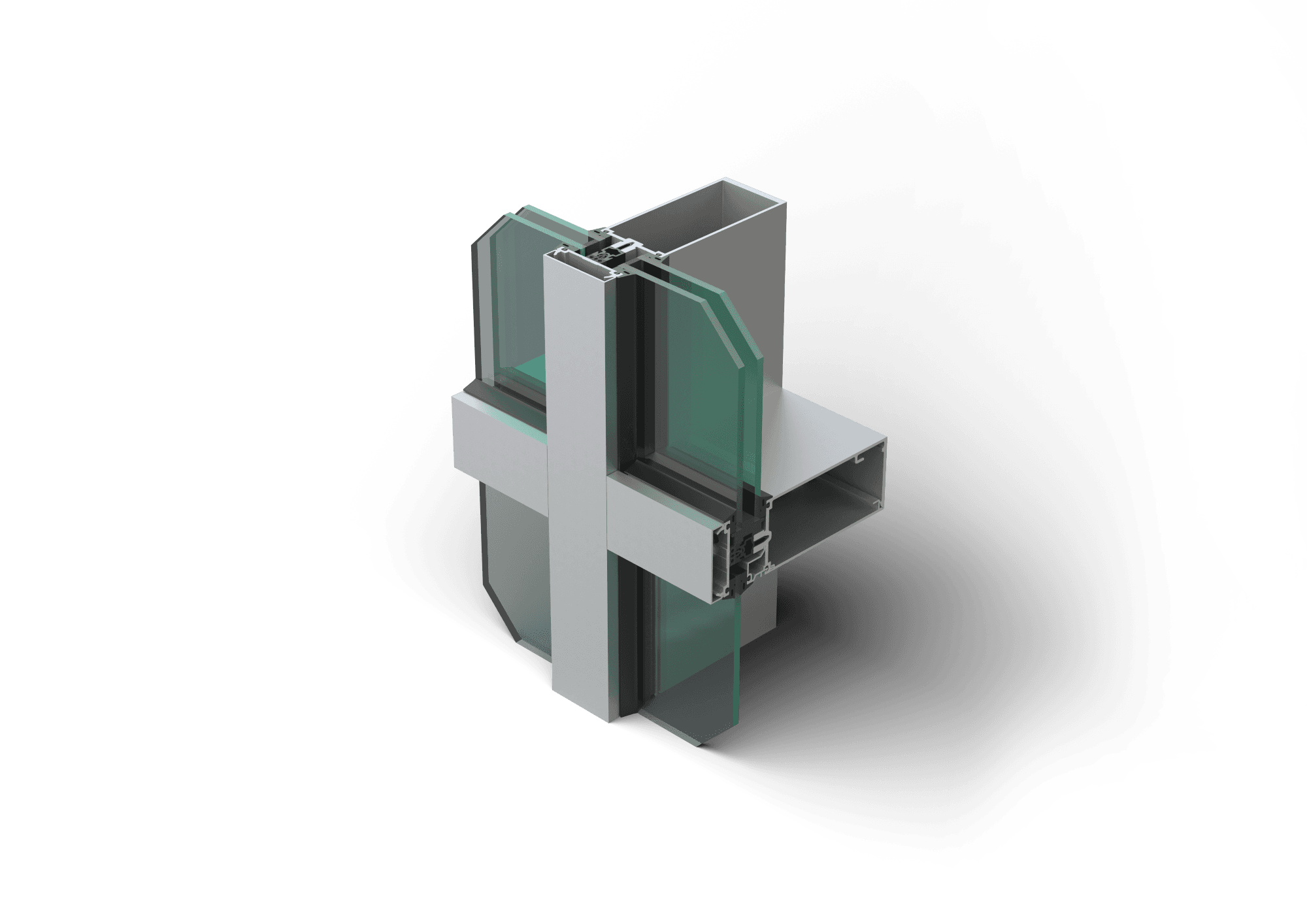

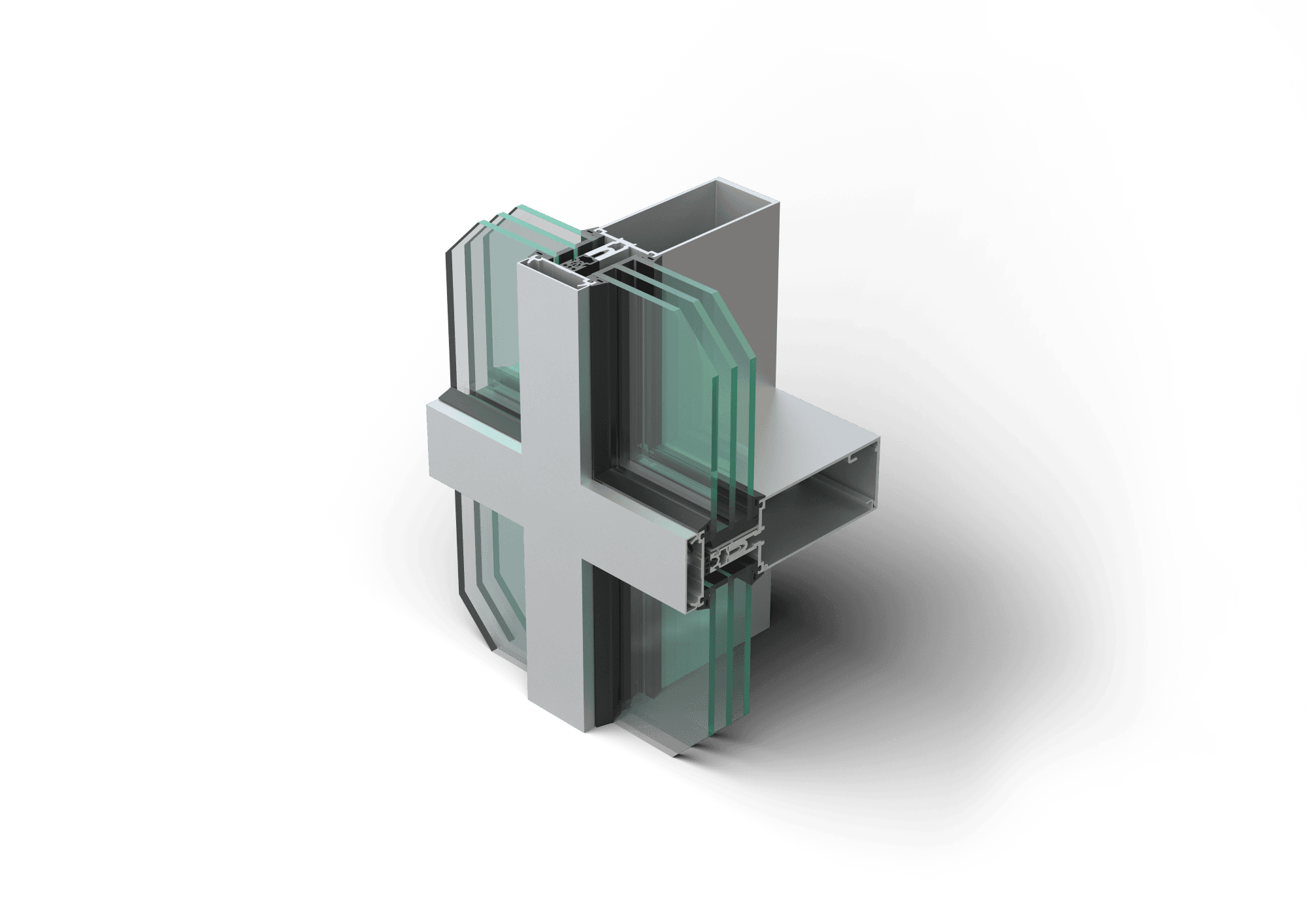

- Plusieurs niveaux de performances thermiques résultant d’une combinaison de:

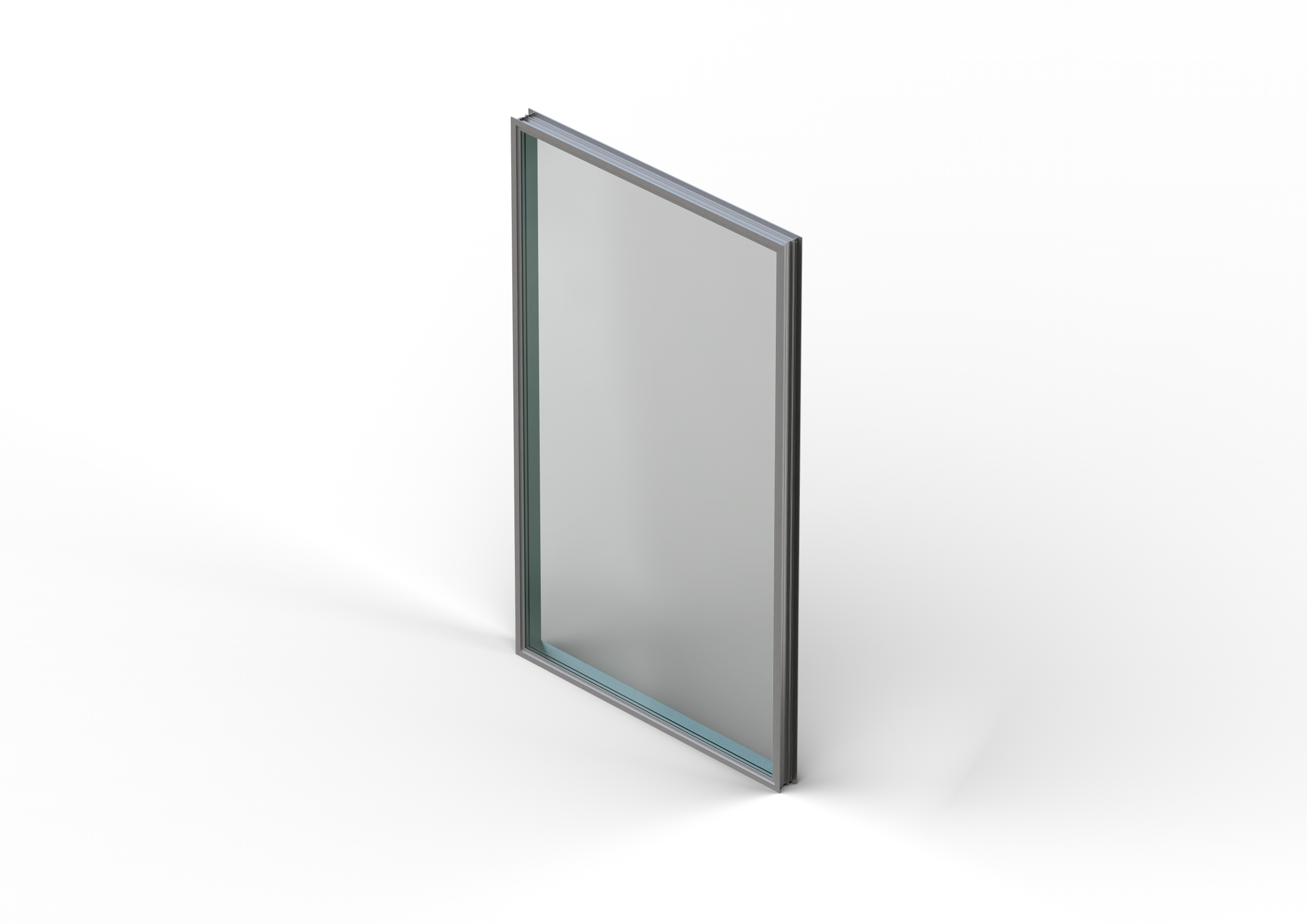

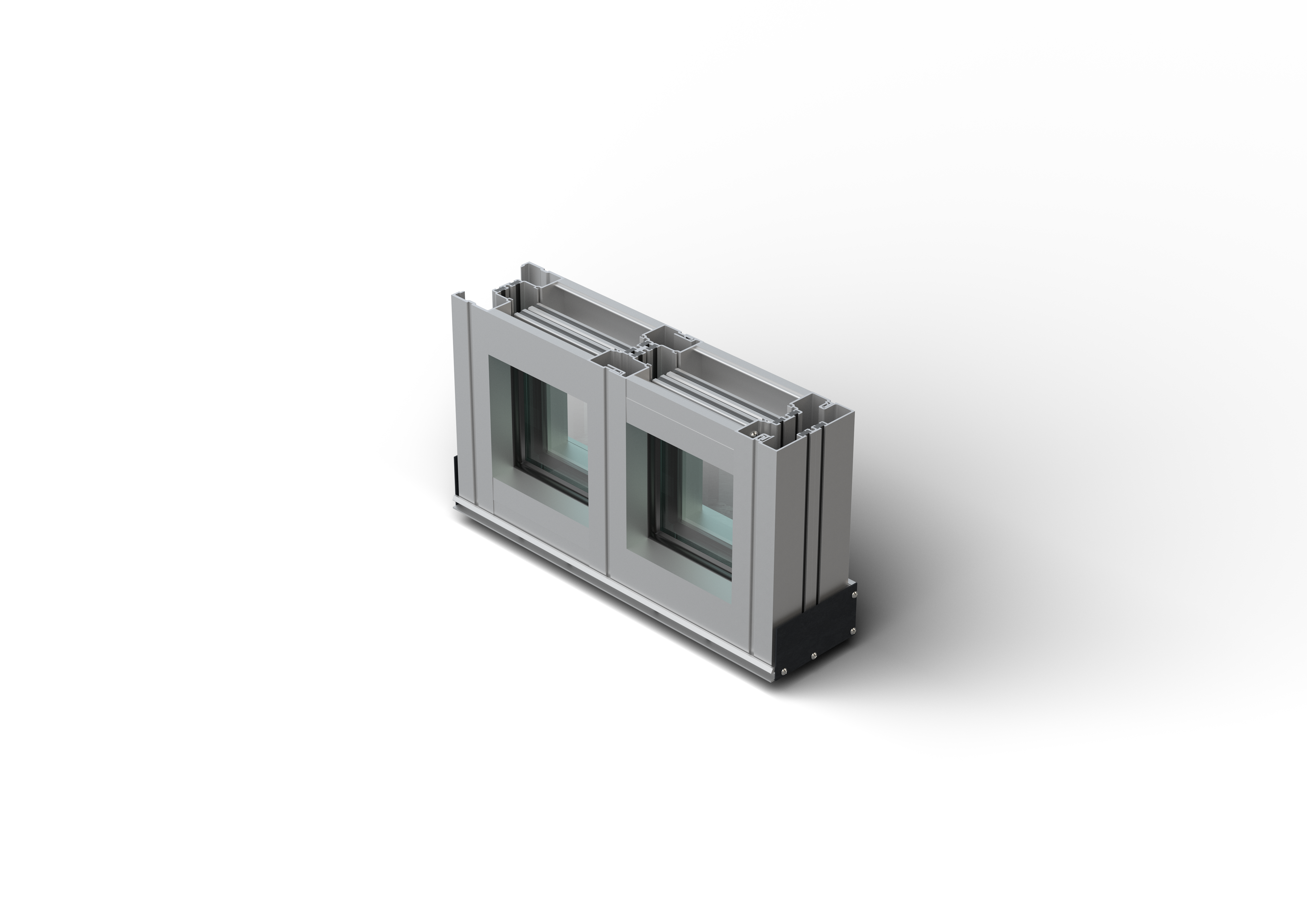

- Verres isolants à double vitrage de 1 po (25,4 mm) ou triple vitrage 1-3/4 po (44,45 mm)

- Plaques de pression en aluminium ou en fibre de verre

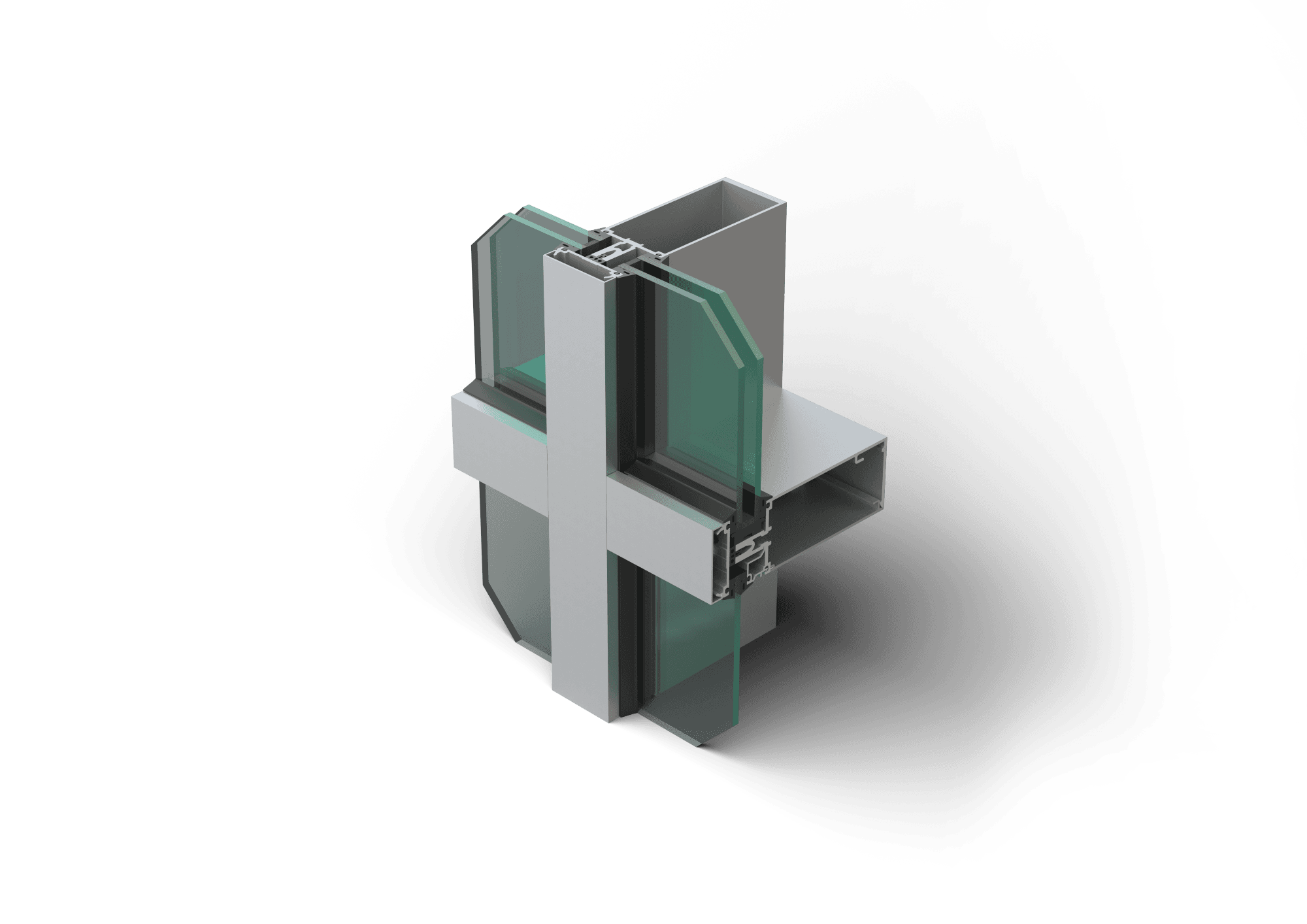

- Conception de barrière thermique pour assurer des performances thermiques élevées sans être sensible à la fatigue thermique comme d’autres matériaux

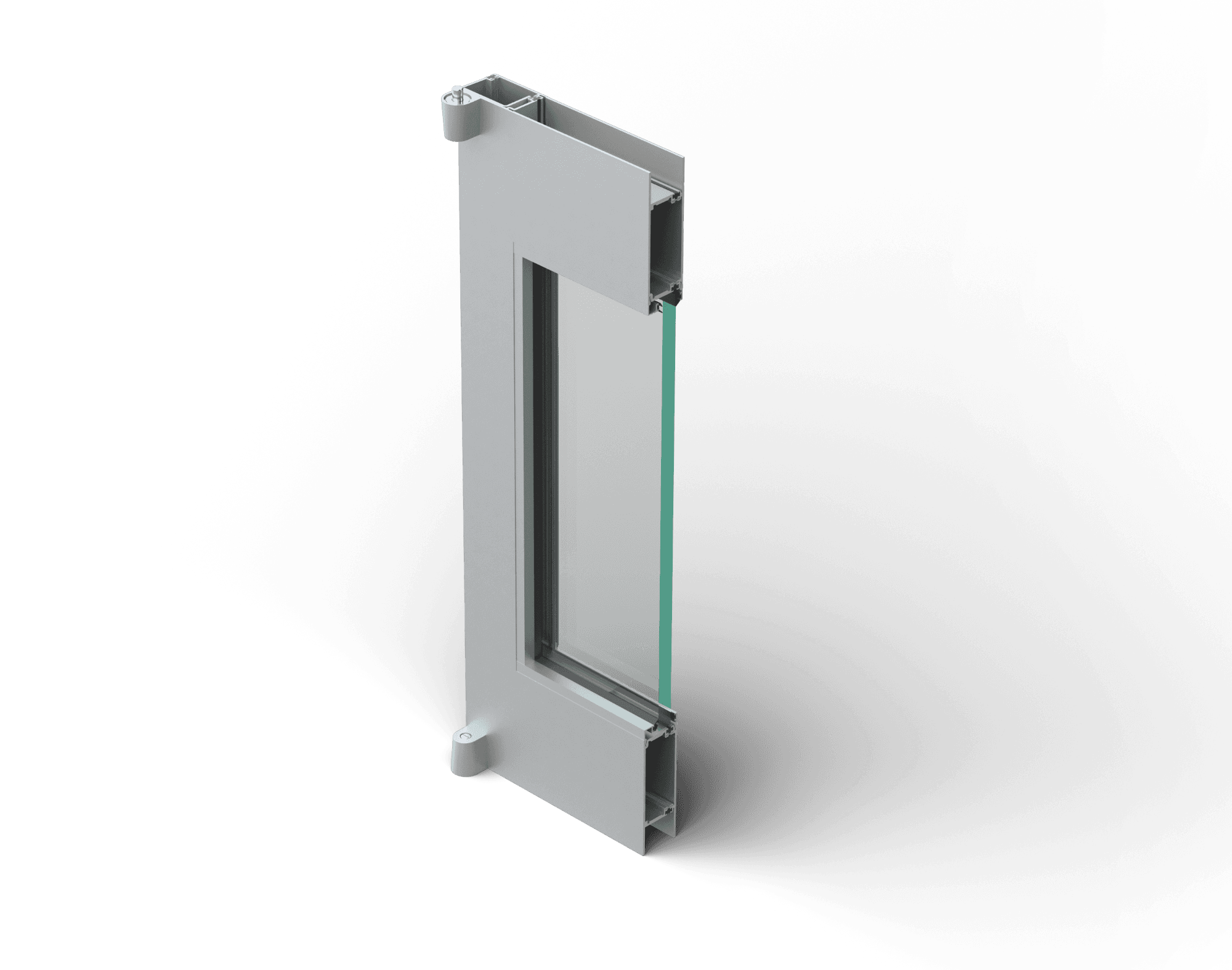

- Intégration transparente avec des entrées et des systèmes de fenêtres hautes performances ou standard

- Angles et évasements disponibles

- Entièrement testé selon les dernières normes de haute performance structurelle, thermique, d’air et d’eau

- Des taquets en verre supportent les vitres isolantes, permettant de plus grandes étendues de verre

- Système à pression équilibrée testé avec pare-vapeur

- Test d’impact humain (AAMA 501.8)

Caractéristiques optionnelles

- Armature en acier

- Écran pare-pluie et backpans

- Couvercles à profil profond et couvercles arrondis

- Meneaux profonds et lourds

- Ensembles de matrices Profit$Maker® Plus disponibles

- Option bicolore

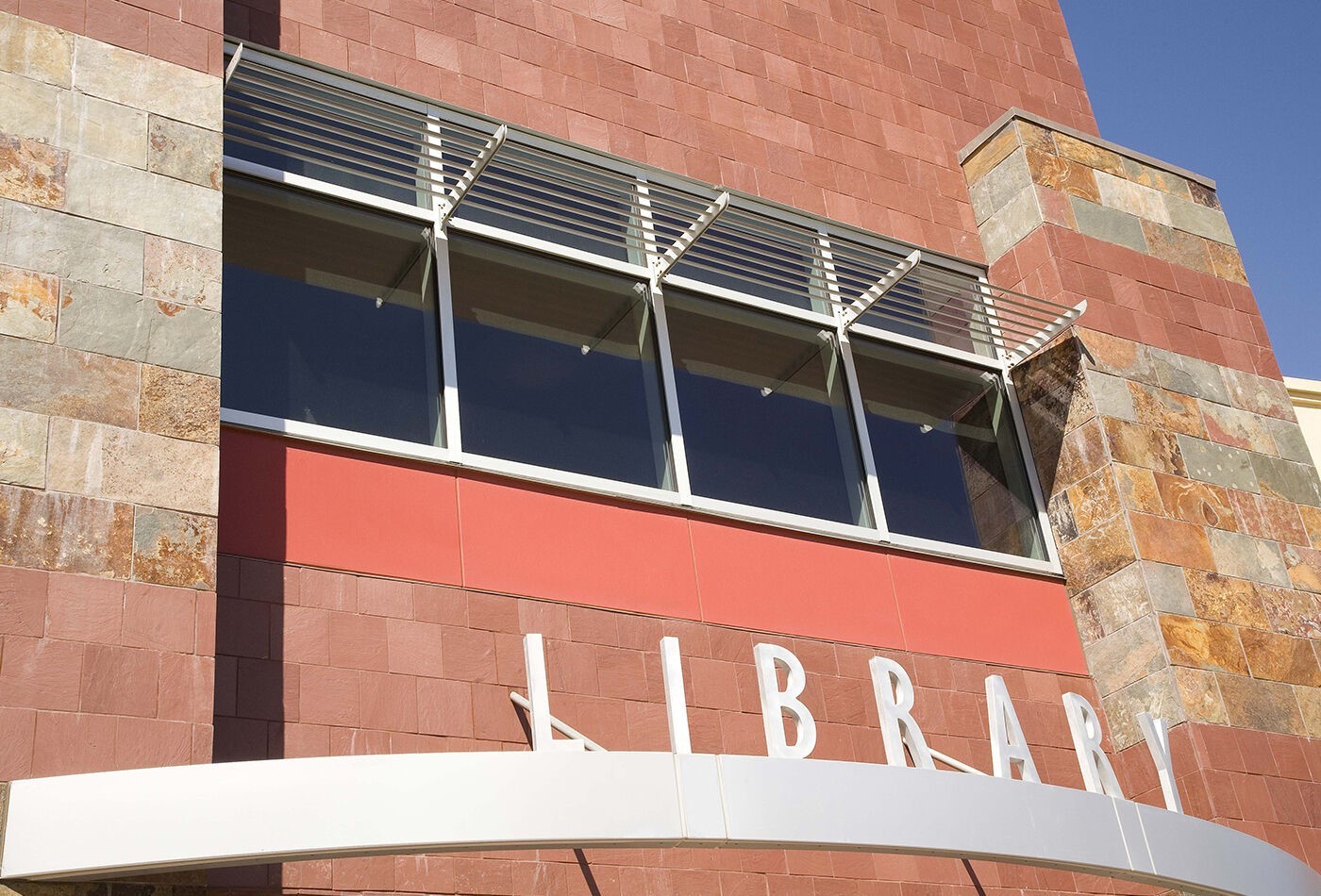

Utilisations du produit

- Idéal pour les applications de faible à moyenne hauteur où des performances thermiques élevées sont souhaitées

- Applications à grande portée

- S’intègre aux entrées Kawneer, aux fenêtres GLASSvent® UT et aux produits de contrôle solaire

Technologie thermique

En savoir plus ici.

1600UT System™1 Curtain Wall - Architectural Detail Manual

17 Mo

Mur-rideau 1600UT System™1 - Manuel de détails architecturaux

17 Mo

1600UT System™1 Curtain Wall - Flyer

274 Ko

Curtain Wall AAMA 501.6 Seismic Test - Flyer

85 Ko

1600UT System™1 & 2 Curtain Wall - Product Green Guide

228 Ko

Traditional Curtain Wall/Aluminum Curtain Wall Systems - EPD

617 Ko

1600UT System®1 Curtain Wall and 1600UT System®2 Curtain Wall Systems - DECLARE Label

803 Ko

1600UT System®1 Curtain Wall and 1600UT System®2 Curtain Wall System - MTS

586 Ko

Brochure sur les finitions

Informations sur les finitions - Manuel de détails architecturaux

238 Ko

Finitions anodisées - Color Chart® (en anglais)

82 Ko

Peinture liquide - Tableau des couleurs - Permadize®.

1 Mo

Peinture liquide - Tableau des couleurs - Permafluor®.

350 Ko

1600UT System™1 Curtain Wall - English

1600UT System™1 Curtain Wall - French

1600UT System™1 Curtain Wall - Spanish

Typical Details with Perimeter Pressure Plate

Typical Details with Thermal Pocket Filler

90° & 135° Corner Details

AA®6400 Window and 1600 GLASSvent® UT Window Details

Entrance Details - Center Hung with COC

Entrance Details - Offset Pivot/Butt Hung with SA COC or Surface Closer

Entrance Details - Offset Pivot/Butt Hung with Surface Closer

Entrance Details - OP/BH with SA COC or Surface Closer-250T Insulpour® Door

Entrance Details - OP/BH with Surface Closer-250T Insulpour® Door

Typical Anchoring & Steel Reinforcing Details

Typical Details with Perimeter Press

Typical Details with Thermal Pocket Filler

90° & 135° Corner Details

AA®6400 Window and 1600 GLASSvent® UT Window Details

Entrance Details - Center Hung with COC

Entrance Details - Offset Pivot/Butt Hung with SA COC or Surface Closer

Entrance Details - Offset Pivot/Butt Hung with Surface Closer

Entrance Details - OP/BH with SA COC or Surface Closer-250T Insulpour® Door

Entrance Details - OP/BH with Surface Closer-250T Insulpour® Door

Typical Anchoring & Steel Reinforcing Details

Typical Details with Perimeter Pressure Plate

Typical Details with Thermal Pocket Filler

AA®6400 Window and 1600 GLASSvent® Window Details

Entrance Details - Center Hung with COC

Entrance Details - Offset Pivot/Butt Hung with SA COC or Surface Closer

Entrance Details - Offset Pivot/Butt Hung with Surface Closer

Entrance Details - OP/BH with SA COC or Surface Closer-250T Insulpour® Door

Entrance Details - OP/BH with Surface Closer-250T Insulpour® Door

Typical Anchoring & Steel Reinforcing Detai

Backpan Details - 1" Infill

Backpan Details - 1-3/4" Infill

Optional Framing Details - 1" & 1-3/4 Infill

Stool Trim Options - 1" & 1-3/4" Infill

Optional 1-1/4" Infill Details

Optional 1-5/16" Infill Details

Typical Details with Perimeter Pressure Plate

Typical Details with Thermal Pocket Filler

90° & 135° Corner Details

AA®6400 Window and 1600 GLASSvent® UT Window Details

Entrance Details - Center Hung with COC

Entrance Details - Offset Pivot/Butt Hung with SA COC or Surface Closer

Entrance Details - Offset Pivot/Butt Hung with Surface Closer

Entrance Details - OP/BH with SA COC or Surface Closer-250T Insulpour® Door

Typical Anchoring & Steel Reinforcing Details

Typical Details with Perimeter Pressure Plate

Typical Details with Thermal Pocket Filler

90° & 135° Corner Details

AA®6400 Window and 1600 GLASSvent® UT Window Details

Entrance Details - Center Hung with COC

Entrance Details - Offset Pivot/Butt Hung with SA COC or Surface Closer

Entrance Details - Offset Pivot/Butt Hung with Surface Closer

Entrance Details - OP/BH with SA COC or Surface Closer-250T Insulpour® Door

Typical Anchoring & Steel Reinforcing Details

Typical Details with Perimeter Pressure Plate

Typical Details with Thermal Pocket Filler

AA®6400 Window and 1600 GLASSvent® UT Window Details

Entrance Details - Center Hung with COC

Entrance Details - Offset Pivot/Butt Hung with SA COC or Surface Closer

Entrance Details - Offset Pivot/Butt Hung with Surface Closer

Entrance Details - OP/BH with SA COC or Surface Closer-250T Insulpour® Door

Typical Anchoring & Steel Reinforcing Details

Details w/Perimeter Pressure Plate

6" Frame Depth (1" Infill)

1600UT System™1 Curtain Wall

1600UT System™1 Curtain Wall

While most of our products are not hazardous in and amongst themselves, hazardous properties can develop when the product is altered through cutting, welding, and grinding. Details on the specific hazards that can develop and the proper protective measures to use can be found in the SDSs.

Arconic’s SDS database provides PDF files of safety information on specific materials. The SDS ID numbers (product code) and description for materials used in Kawneer products are listed below.

SDS # DESCRIPTION / TITLE

1405 – Kawneer Thermal Break Filled Extrusions

1385 – Kawneer Acrylic Paints

1386 – Kawneer Fluoropolymer Paints

1526 – Kawneer Bloomsburg Solvent Recovery Still Residuals

1387 – Painted Architectural Aluminum Extrusions

509 – Aluminum Extrusions, Anodized Aluminum Products

Search Arconic’s SDS database for safety information on specific materials.

Search Instructions

Kawneer - CA Prop 65 Warnings - English

139 Ko

Material & Workmanship - English

185 Ko

Material & Workmanship - French

190 Ko

Anodized Finishes Warranty - English

523 Ko

Anodized Finishes Warranty - French

517 Ko

Painted Finishes Warranty - English

557 Ko

Painted Finishes Warranty - French

538 Ko

Insulating Glass Warranty - English

498 Ko

Insulating Glass Warranty - French

499 Ko

Laminated Glass Warranty - English

122 Ko

Laminated Glass Warranty - French

123 Ko